-

-

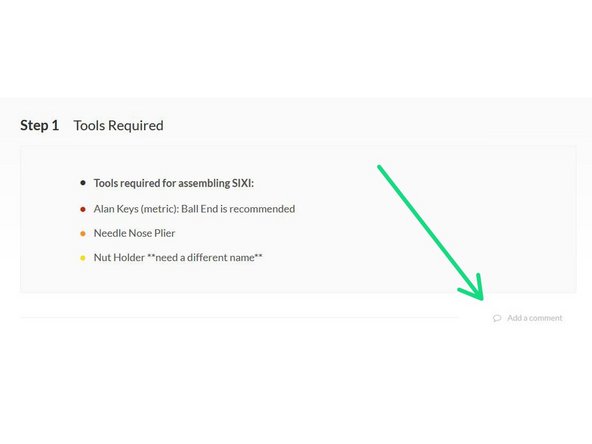

Tools required for assembling SIXI:

-

Alan Keys (metric): Ball End is recommended

-

5mm Hex Nut Driver

-

Needle Nose Plier

-

-

-

Most 3D printed parts are labelled to verify the package and versions.

-

-

-

Read each chapter before you start work. Catch confusing things early!

-

Always follow every step in order.

-

If a step is unclear, use the comment section below it to let us know.

-

Steps may be color coded and have matching colored symbols on the pictures. A single picture could have more than one symbol.

-

-

-

If you are 3D printing parts yourself, make sure to calibrate your printer! Bad tolerances will make gearboxes either (A) sloppy or (B) so tight they don't move.

-

-

-

[3D] Electronic Case Package

-

Robot Electronics

-

Alan Keys

-

Flat Screw Driver

-

Needle Nose Pliers

-

Multimeter

-

Ferrule Crimper (optional)

-

-

-

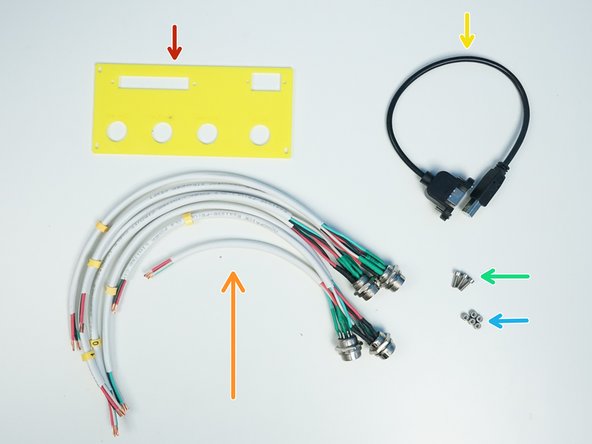

Prepare the following components:

-

ABS Junction Box {380x260x105mm}

-

[3D] - 7E-plug wall adapter

-

Aviation GX16-8p Cable M/O (wire assembled and numbered)

-

USB-B M/F Panel Mount Extension

-

M3x10mm Screws (x3)

-

M3 Nylock Nuts (x5)

-

-

-

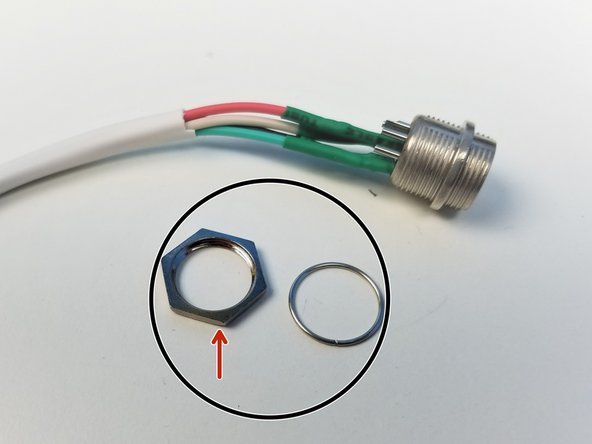

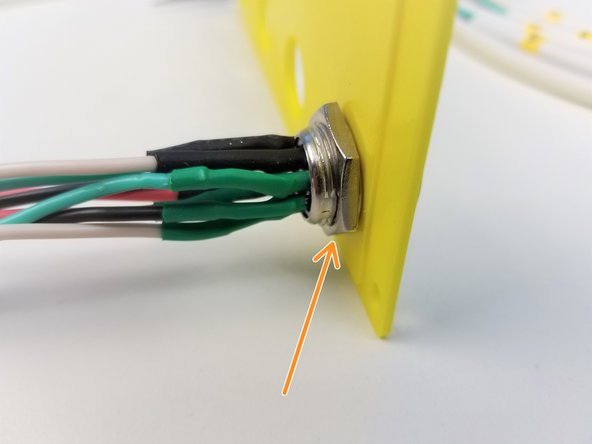

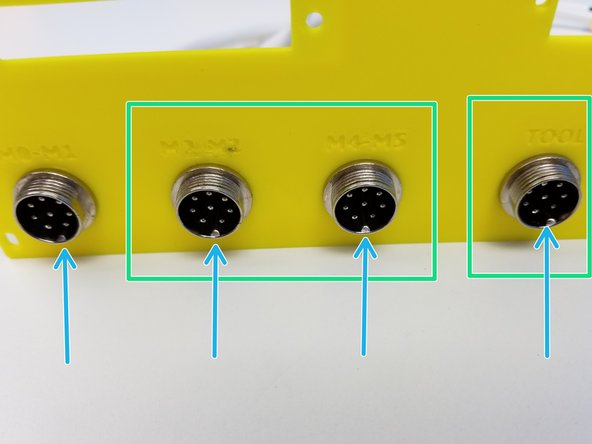

Unscrew the Wall Mount Nuts from each connectors

-

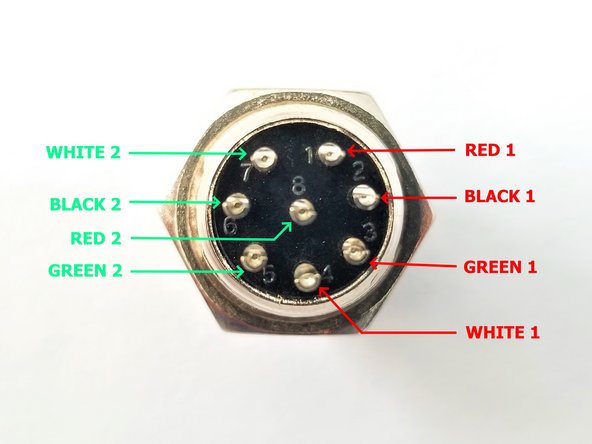

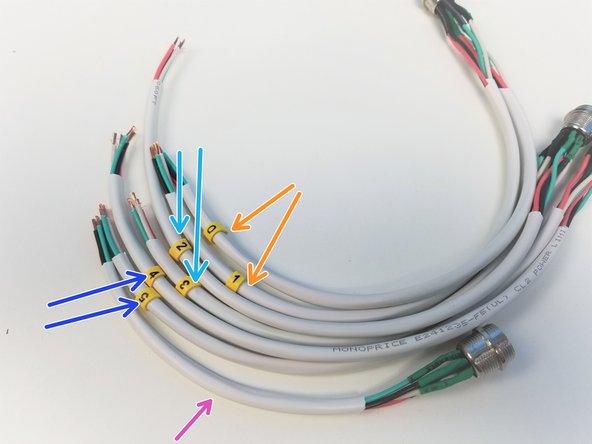

Each Connectors have 2 sets of 4pin wires soldered in this specific manner

-

The wires are cut to length as follows:

-

0 & 1 = 370mm & 370mm respectively

-

2 & 3 = 370mm & 270mm respectively

-

4 & 5 = 340mm & 310mm respectively

-

Not Labelled = Tool --> 190mm

-

-

-

Familiarize yourself with the panel. The back side has a lip and the front side is labelled with each connector.

-

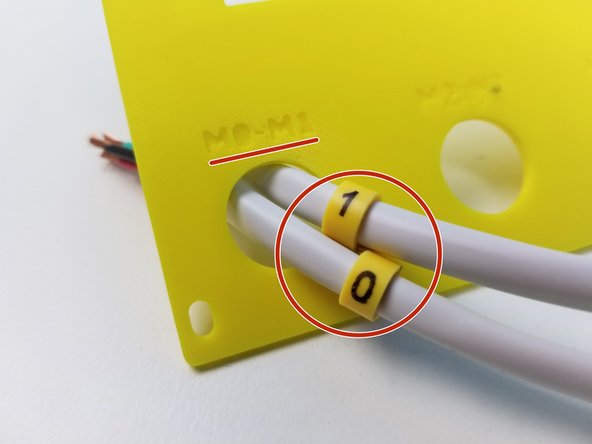

Feed the Cables through the Wall Adapter as labelled. Make sure the long end of the cable ends up on the back side of the panel.

-

Tighten the Mounting Nut that was unscrewed from the previous step

-

Repeat the same process with the rest of the connectors

-

Be sure the alignment mark on the plug to be in the bottom center

-

-

-

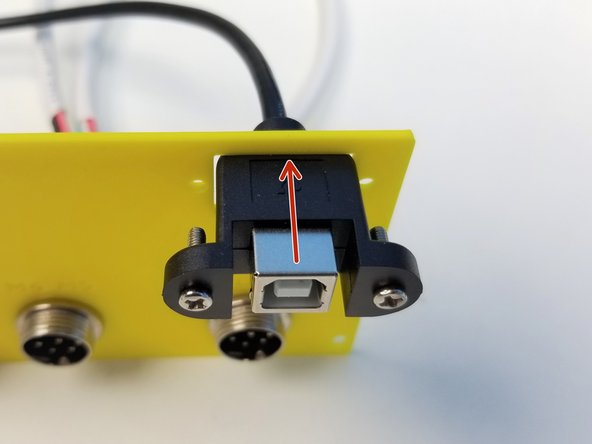

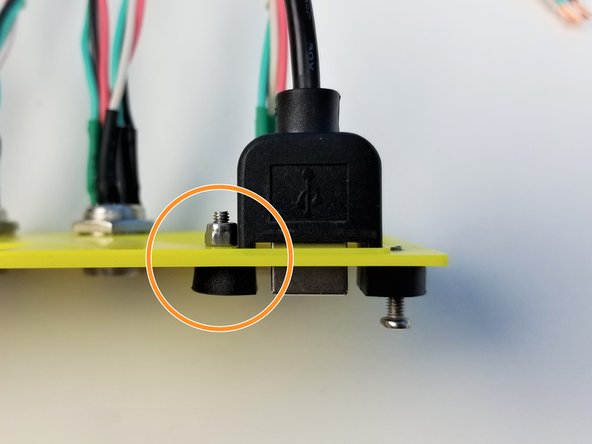

USB Extension Cable comes with M3x10mm Philip Head Screws

-

Feed the USB Cable through the Case Wall Adapter

-

Use M3 Nylock Nut to secure USB Extension Cable in place

-

Only tighten the side furthest from the edge

-

-

-

Insert the Case Wall Adapter into the Case and secure its place using the M3x10mm Screws.

-

Use the M3 Nylock Nuts on the inside of the case but don't tighten it too much. Case wall Adapter should be able to slide along the wall

-

-

-

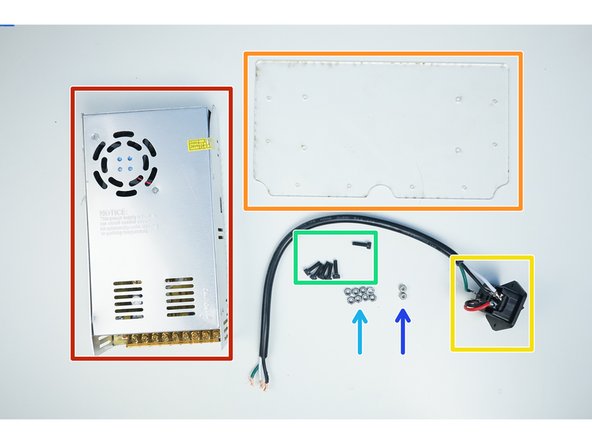

Prepare the following components:

-

Power Supply 24V-20A

-

Acrylic PSU Mounting Plate

-

Rocker Switch

-

M4x14mm Screws (x6)

-

M4 Hex Nuts (x8)

-

M4 Nylock Nuts (x2)

-

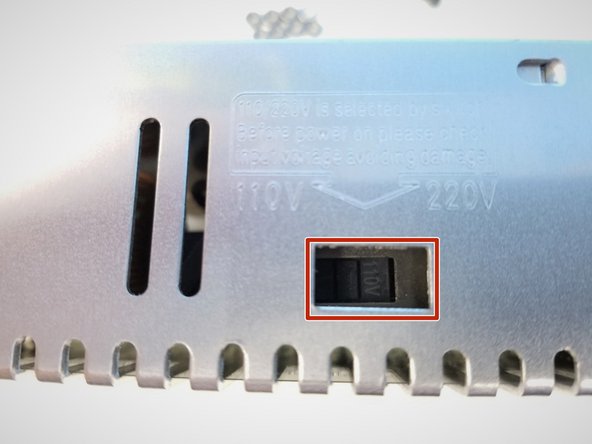

Make sure the Power Supply is set to the correct voltage, in Canada, we use 110V

-

-

-

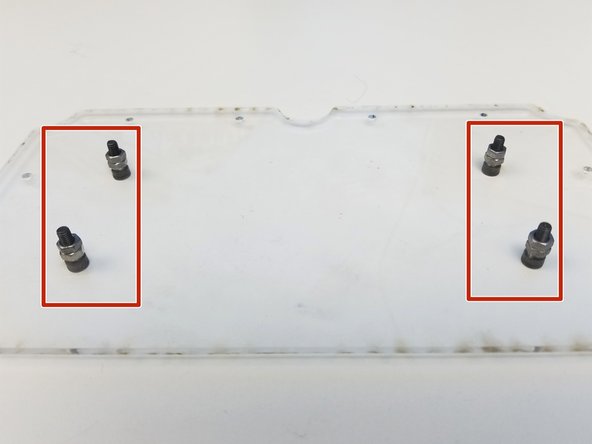

Use two M4 Hex nuts per M4x14mm Screws as spacer on the Acrylic Mounting Plate

-

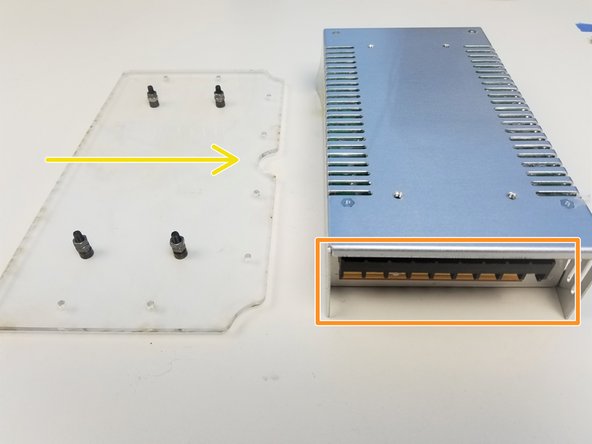

Align the PSU and the Acrylic Mounting Plate as shown in the figure exactly

-

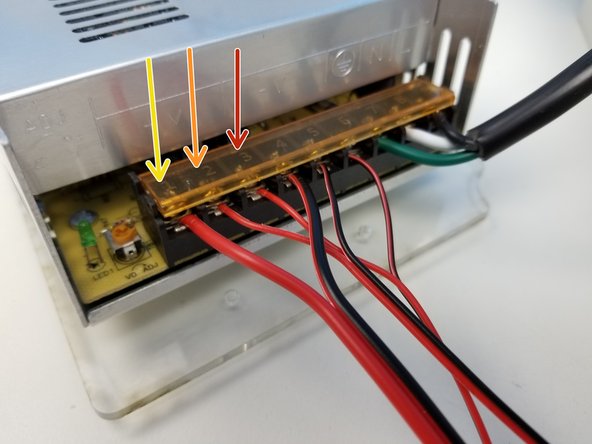

Take a closer look on the Screw Terminal of PSU

-

Take a closer look on the "Half Moon" cut on the Plate

-

Flip the Acrylic Mounting Plate on to the PSU

-

DON'T tighten 1 screw all the way at a time, this will cause the plate to flex and cause it break

-

-

-

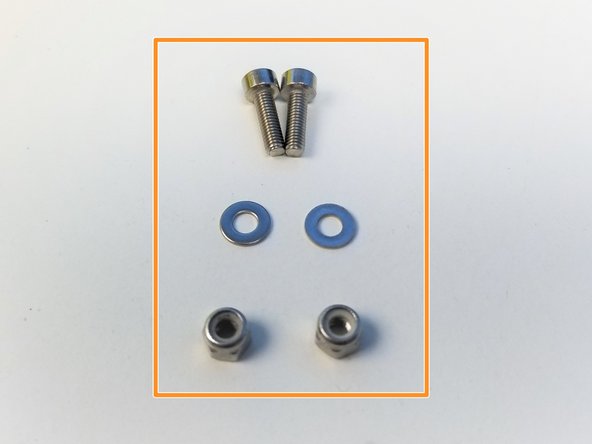

Insert the Rocker Switch into the Machined Case.

-

Some version of Rocker Switch has smaller mounting holes

-

if this is the case, use the M3x10mm Screws, Washers and Nylock Nuts

-

If not, use M4x14mm Screws and M4 Nylock Nuts

-

Secure the Rocker Switch with the fasteners

-

Notice the Soldering Patterns AND Length

-

18AWG Power Wires 65mm long

-

3 Wire Power Cable 365mm long

-

-

-

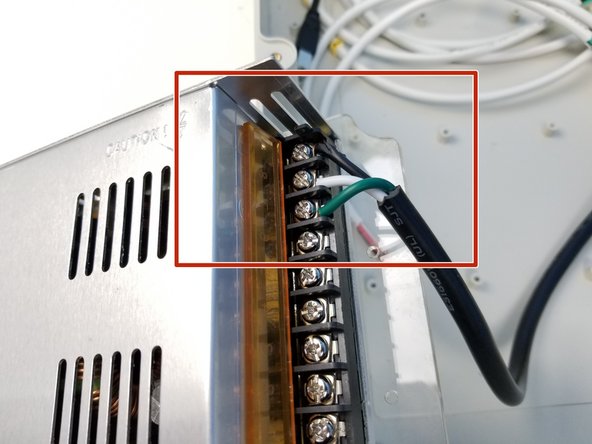

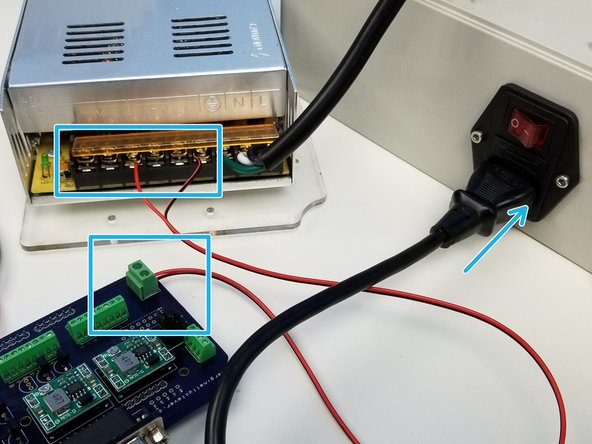

Secure the Power Cable to the PSU Screw Terminals

-

Test the Rocker Switch and PSU by connecting the Power Plug and turning the Switch ON

-

Be careful to NOT touch the screw terminals with your bare hands.

-

If the Green LED light turns on, it's a good sign

-

Use the Multimeter to make sure the output voltage is approximately 24V, adjust using the Philip Head Screw

-

Left 3 terminals are Positive Output

-

Middle 3 terminals are Ground/Negative Output

-

Once test is successful, Turn off the Power using the Switch and unplug the Power Plug

-

-

-

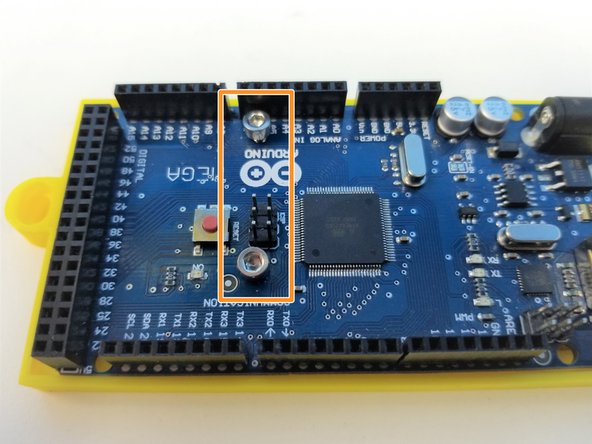

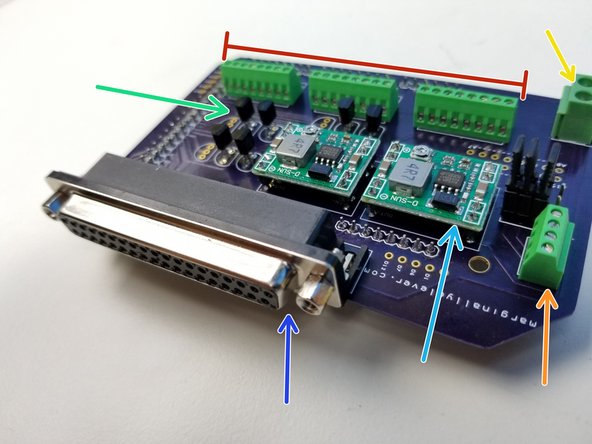

This custom Arduino Mega Shield can be ordered directly and contains the following parts:

-

Screw Terminal 8p - 2.54mm (x3)

-

Screw Terminal 4p - 2.54mm (x1)

-

Screw Terminal 2p - 3.5mm (x1)

-

NPN Transistor 2N2222A (x6-9)

-

Voltage Regulator MP1584EN (x2)

-

D-SUB F-Conn right-angle 37p

-

The voltages in the MP1584EN must be adjusted before we connect this to the Arduino Mega. Incorrect voltage could damage the electronics.

-

-

-

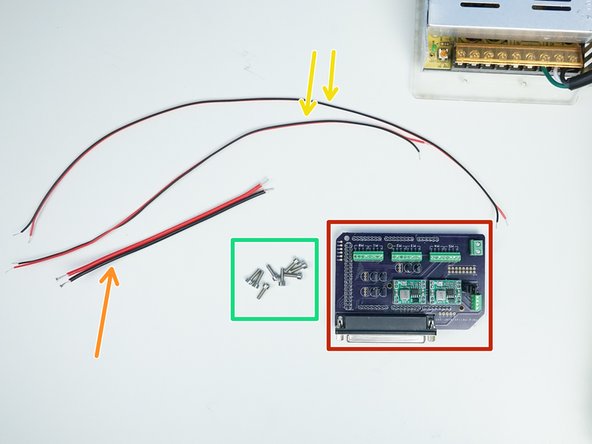

Prepare the following components:

-

Arduino Mega Shield

-

2-Wire Power Cable 18AWG - [160mm]

-

2-Wire Power Cable 22AWG - [335mm & 420mm]

-

M3x8mm Screws (x8)

-

Connect the PSU and Mega Shield using the 22AWG 420mm long wires. Connect the plug to the Switch and turn the power ON

-

Test the LEFT MP1584EN output voltage to be 6V or whichever voltage your gripper servo needs, adjust using the potentiometer

-

Test the RIGHT MP1584EN output voltage to be 10 -12V for powering Arduino Mega .

-

-

-

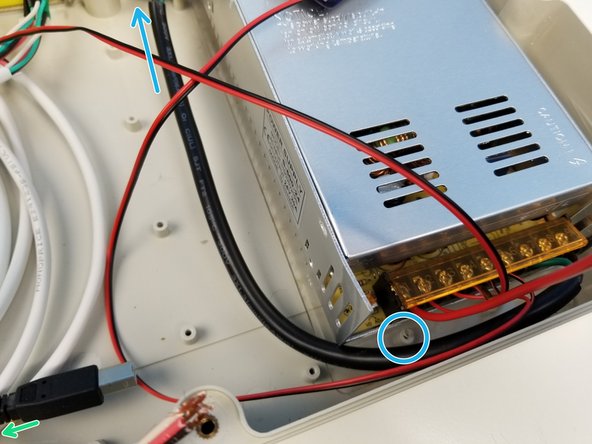

Connect the rest of the power Wires

-

Small Stepper Driver Wires (22AWG 335mm long)

-

Big Stepper Driver Wires (18AWG 160mm long)

-

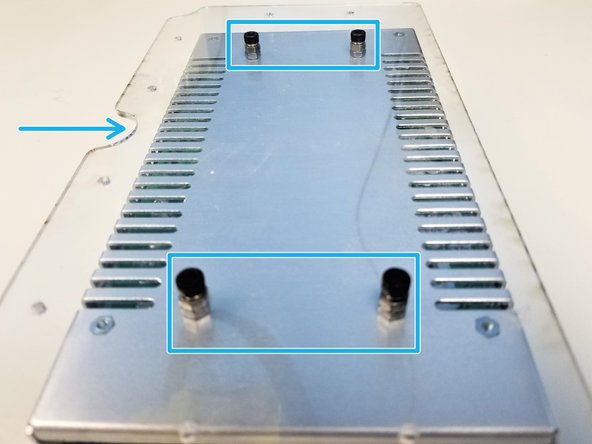

Using a wire cutter to snip two pegs positioned with respect to the Rocker Switch on the top right corner of the picture.

-

Align the Half Moon slot and secure the mounting plate to the Case using M3x8mm Screws in the available spots around PSU.

-

-

-

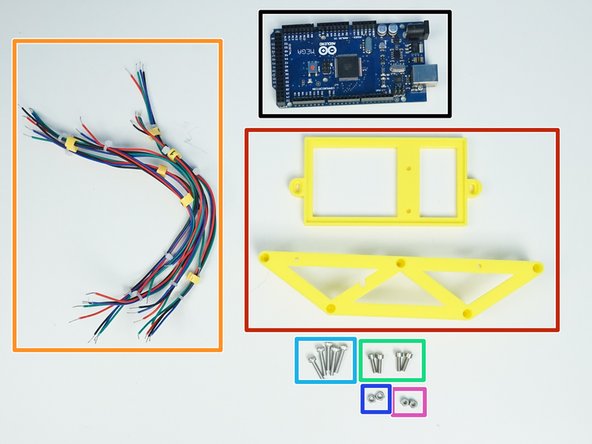

Prepare the following components:

-

Arduino Mega 2650

-

[3D] Arduino Tray and Standoffs

-

4-Wire Signal Cable 22AWG {for Motor}

-

M3x10mm Screws (x4)

-

M3x16mm Screws (x5)

-

M3 Hex Nuts (x2)

-

M3 Nylock Nuts (x2)

-

-

-

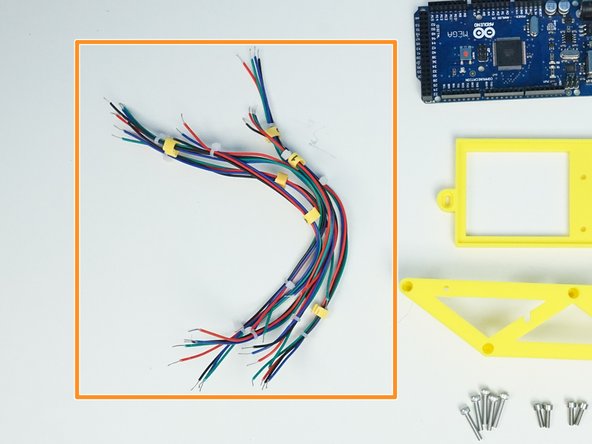

Length of each 4-pin 22AWG wires are listed as below:

-

0 -> 210mm

-

1 -> 210mm

-

2 -> 200mm

-

3 -> 165mm

-

4 -> 185mm

-

5 -> 225mm

-

-

-

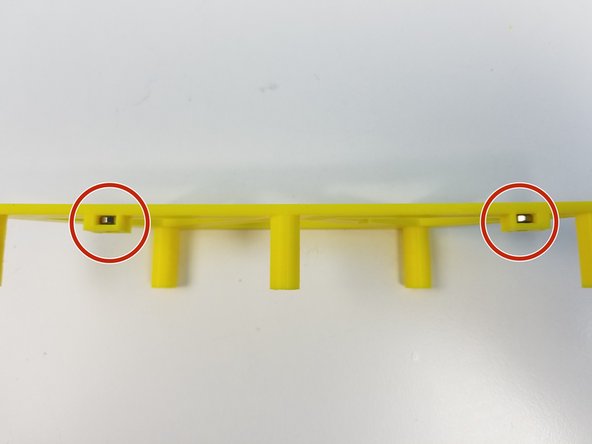

Insert M3 Hex Nuts in the side slot of the Arduino Standoff

-

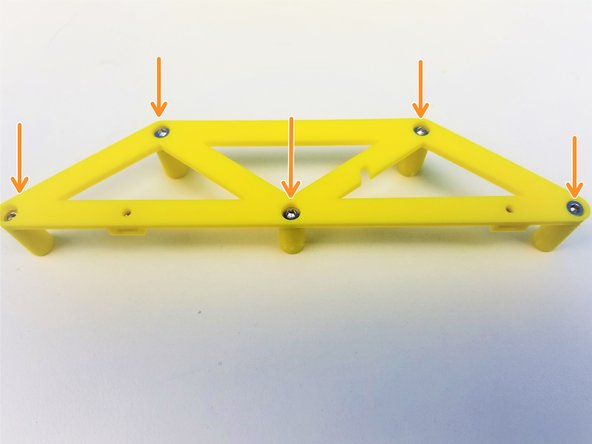

Partially screw in M3x16mm Screws for easier assembly

-

Secure the Standoff to the Case by tightening the Screws in place.

-

Notice the Orientation of the Standoff as well as the position of the cables relative to the pegs of the Standoff

-

-

-

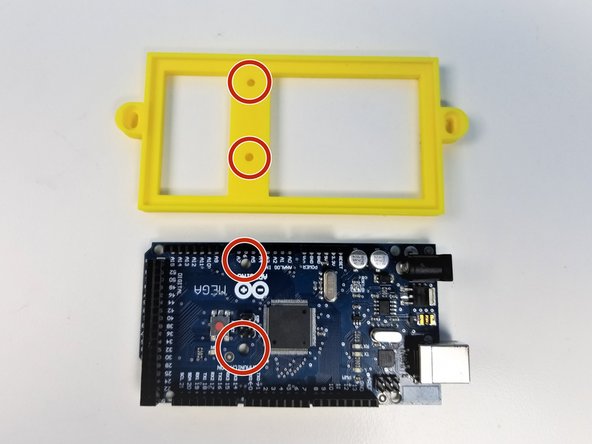

Align the Holes on the Tray and the Arduino Mega

-

Use the M3x10mm Screws and M3 Nylock Nuts to secure the Arduino to the Tray

-

Make sure to tighten the screws just enough to hold them together, No more, since over-tightening the screws can damage the board.

-

-

-

Insert the Mega Shield to the Arduino Mega

-

Make sure you have set the voltage regulator in Step 11 before going forward

-

Remove the hex head screw from the Right Angle D-Sub Connector

-

-

-

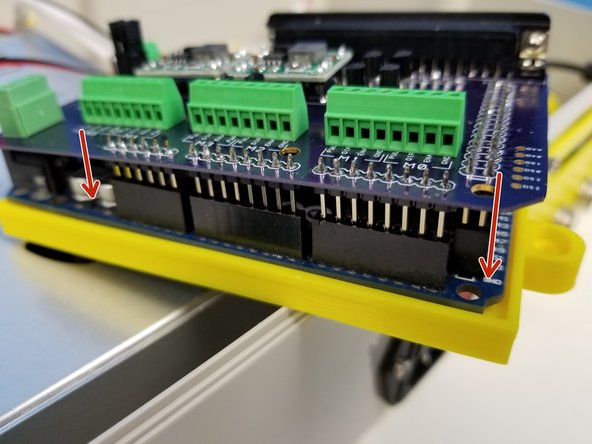

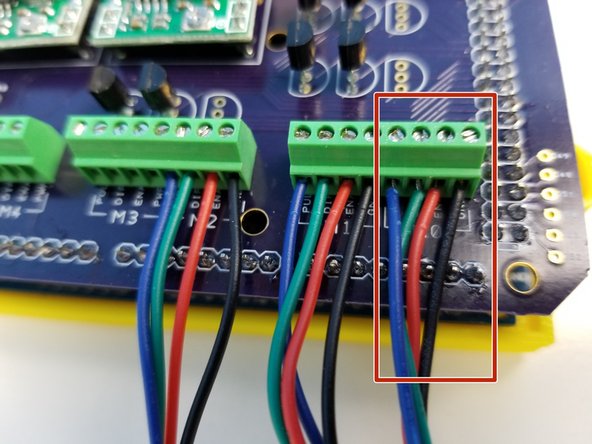

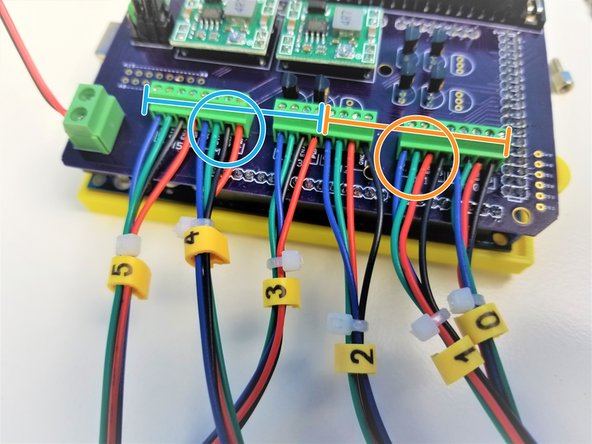

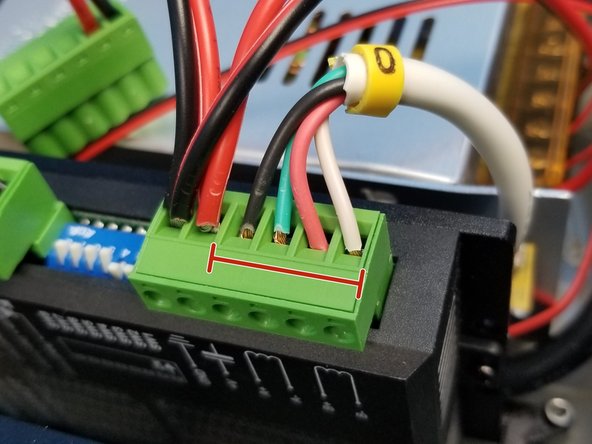

Start with Motor 0 signal cable to the Right most connector labelled "M0"

-

M0, M1 and M2 follows the same color pattern

-

from the right, Black, Red, Green, Blue

-

M3, M4, M5 follows a different color pattern from M0-M2,

-

from the right, Red, Black, Green, Blue

-

-

-

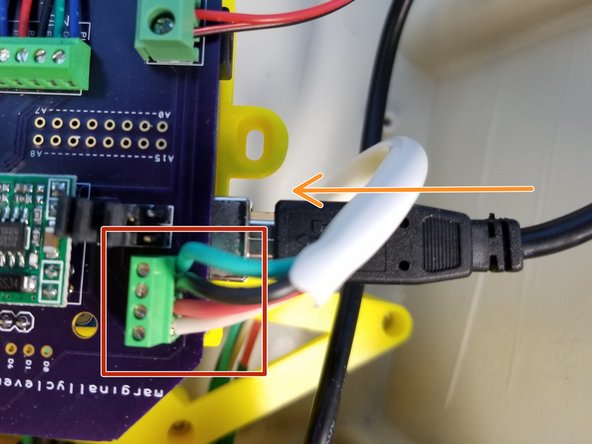

Insert the "TOOL" Cable in the specific order:

-

from the top, Green, Black, Red, White

-

Insert the USB Extension Cable in the Arduino

-

-

-

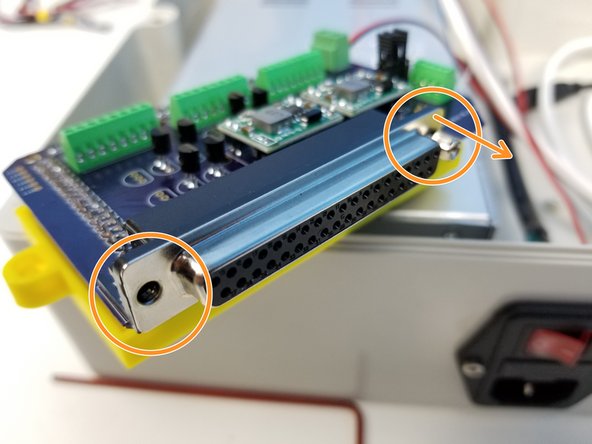

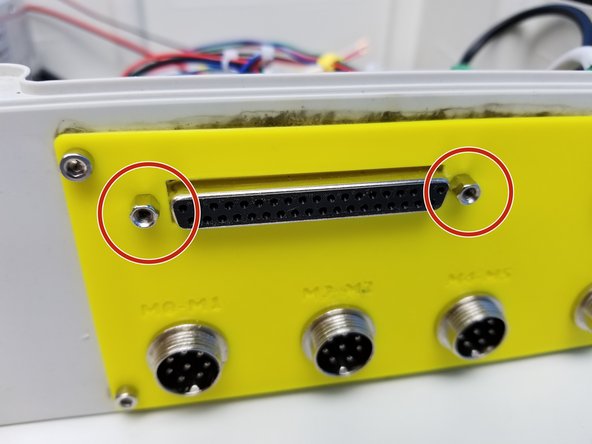

Secure the Right Angle D-Sub Connector to the Case Wall Adapter slot using the Hex Head Screws

-

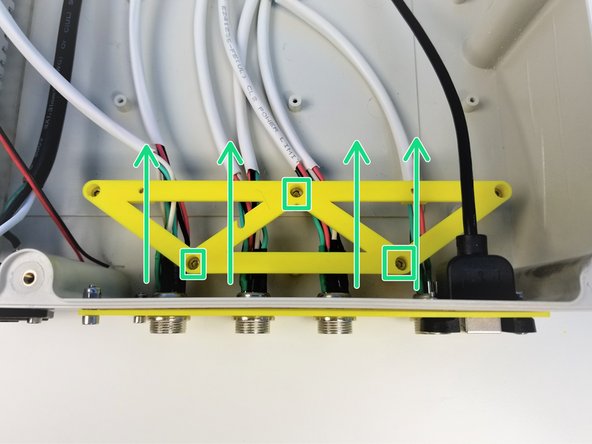

Align the Tray to the Standoff and secure it using the M3x10mm Screws

-

Once everything is aligned, secure this alignment by tightening the screw and the nut on the Case Wall Adapter

-

-

-

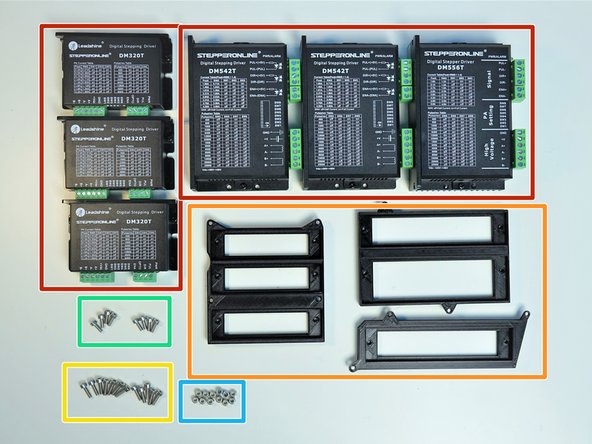

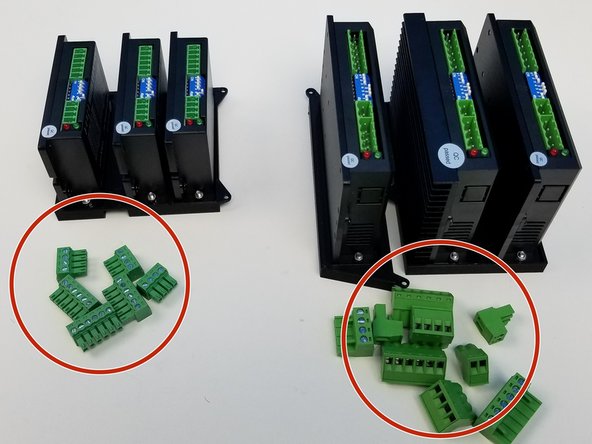

Prepare the following components:

-

Stepper Drivers [DM320T & DM542T & DM556T]

-

[3D] Stepper Driver Adapters

-

M3x10mm Screws (x12)

-

M3x8mm Screws (x9)

-

M3 Nylock Nuts (x12)

-

-

-

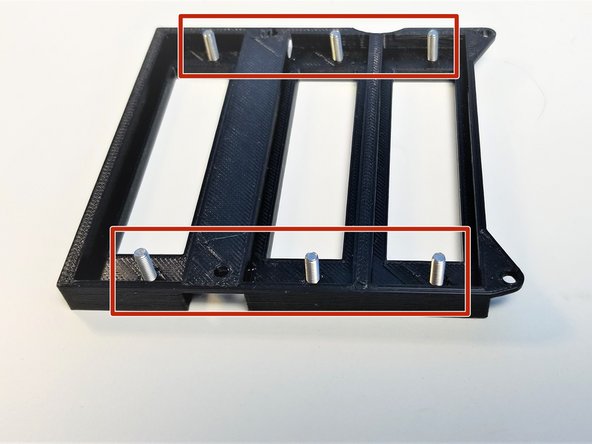

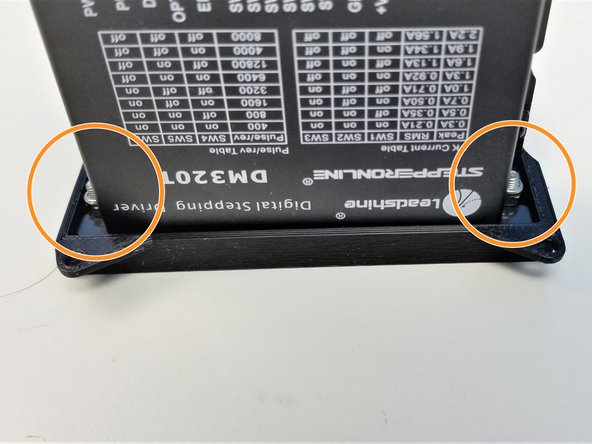

Starting with the Smaller "DM320T" Drivers, screw in M3x10mm Screws in the Adapter with 3 small slots

-

One driver at a time, secure the drivers to the adapter using M3 Nylock Nuts, use Needle Nose Plier to hold the nuts.

-

Repeat the process for the rest of the DM320T Drivers

-

-

-

There are two DM542T Drivers and one DM556T Driver, DM556T Driver is the one with a big Heat Sink in the back

-

Repeat the same process as previous step:

-

Adapter with 2 Slots, fits each DM542T and DM556T

-

Adapter with a single slot fits one DM542T Driver

-

-

-

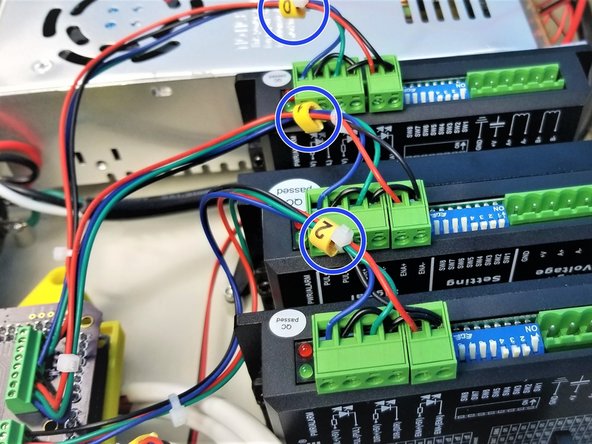

Pull all the Screw Terminal Blocks off from the Drivers

-

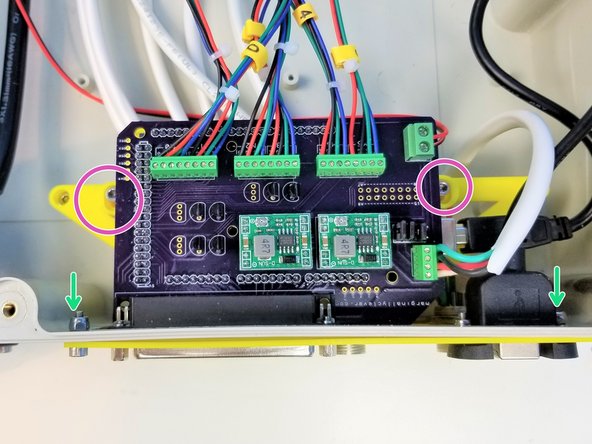

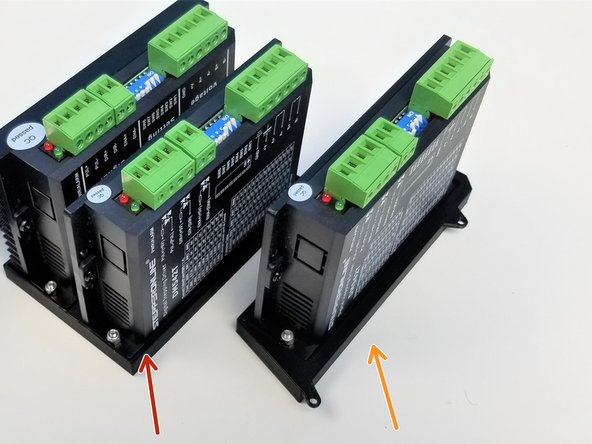

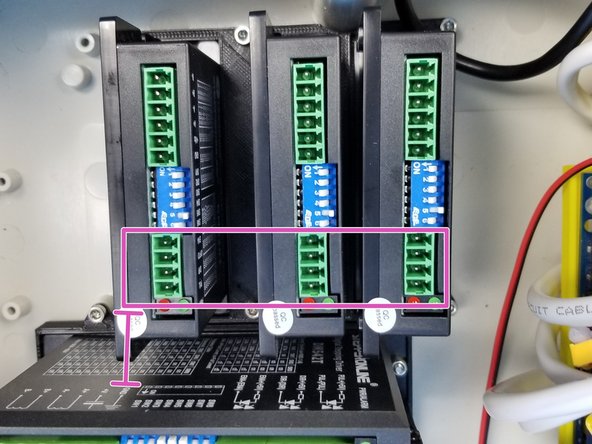

Starting with a single DM542T Driver Adapter, secure each drivers to the Case

-

Make sure the adapters are aligned as shown in the picture, Label on the DM542T and DM556T Drivers are facing away from the PSU

-

For DM320T Drivers, 4 pin side is closer to the Label of DM542T Driver

-

-

-

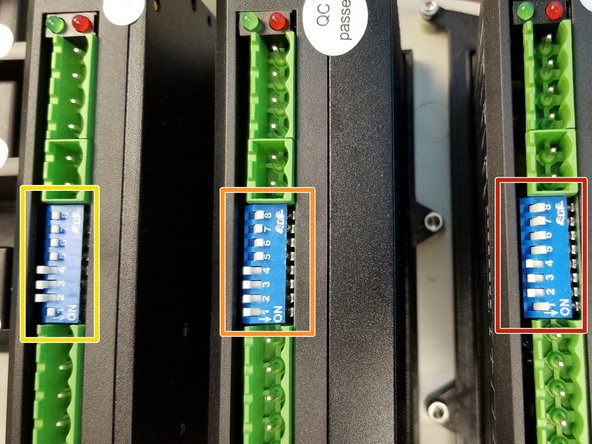

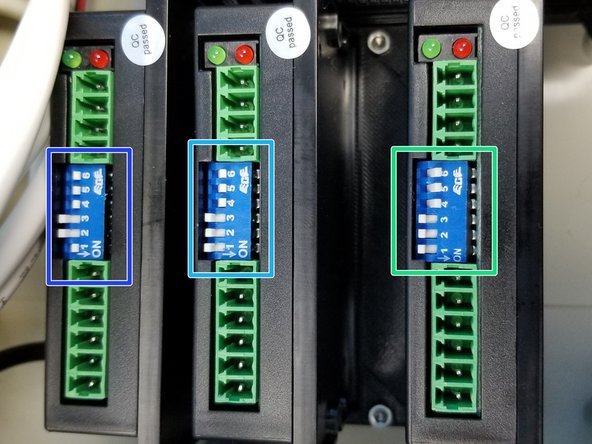

Set the switch to the following mode, it'll follow the Binary scheme, 1 = On, 0 = Off, starting from switch 1 in ascending order

-

DM542T -> 10001111

-

DM556T -> 00001111

-

DM542T -> 10001111

-

DM320T-Right -> 000111

-

DM320T-Middle -> 000111

-

DM320T- Left -> 100111

-

-

-

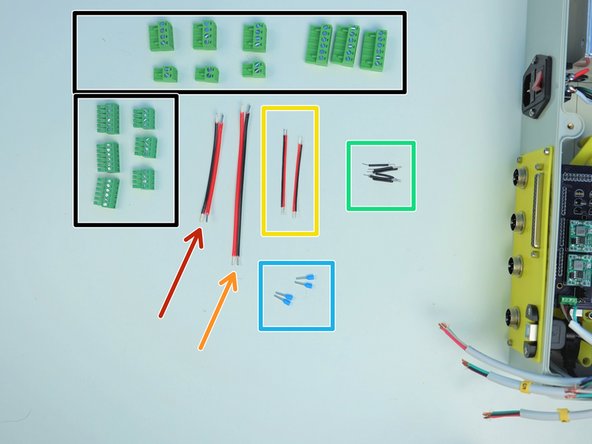

Prepare the following components:

-

Screw Terminal Blocks from the Drivers

-

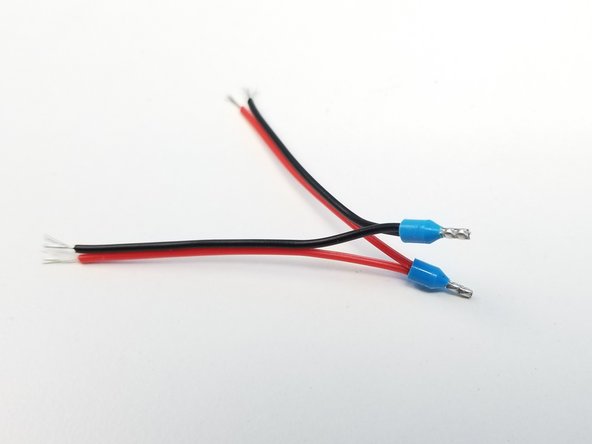

2-pin Power Wires 18AWG 90mm

-

2 pin Power Wires 18AWG 130mm

-

2 pin Power Wires 22AWG 65mm (x2)

-

22 AWG solid Wires Black 30mm (x6)

-

[Opt] - Ferrule Crimp Pins (x4)

-

-

-

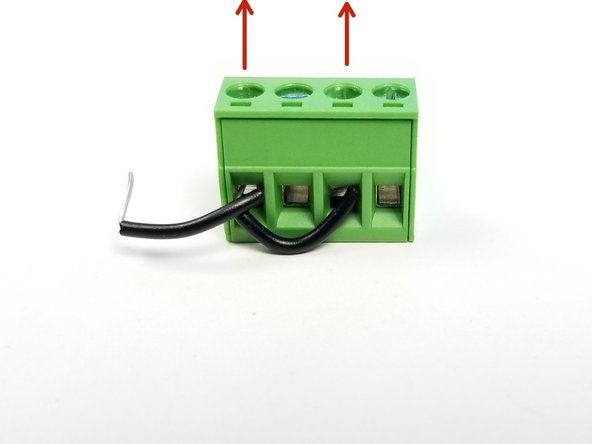

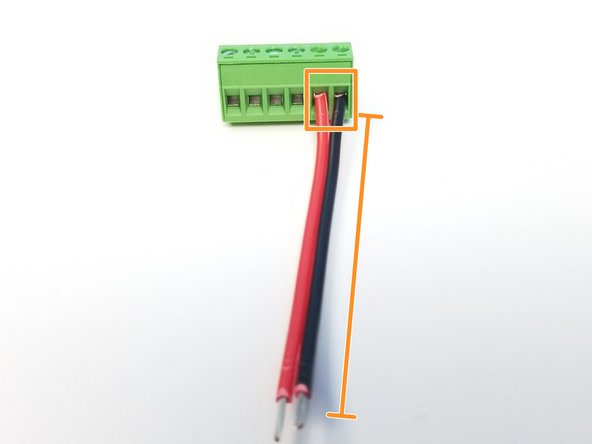

Grab one of the Bigger Driver's 4-pin Screw Terminal and wire it as shown in the first picture, Screw Head is pointing UP

-

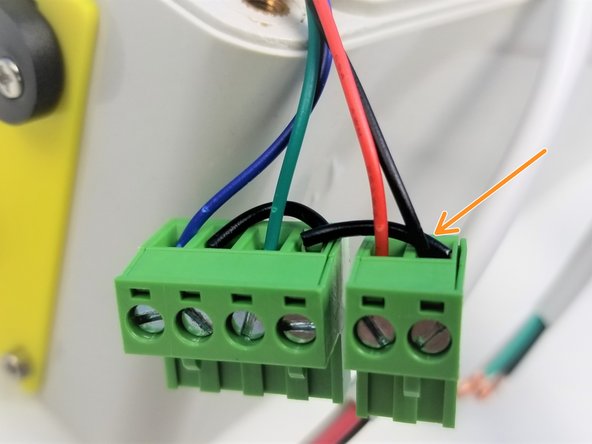

Starting with M0 Cables that's already attached to Arduino Mega Shield, secure the wire as shown in the second picture.

-

notice there are 2 black solid wires in the right most pin of the 2-pin connector

-

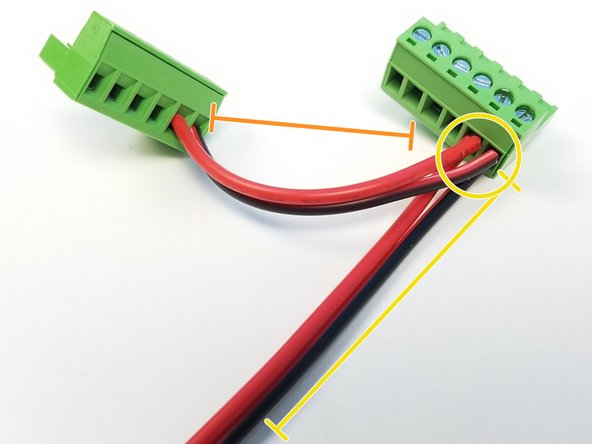

Repeat the same process for the M1 and M2 Drivers, and plug them as shown in the third picture.

-

-

-

Starting with the M3 signal cable, attach them and plug them in the corresponding driver as shown in the first picture,

-

Repeat the process for M4 and M5 drivers, notice the labels

-

-

-

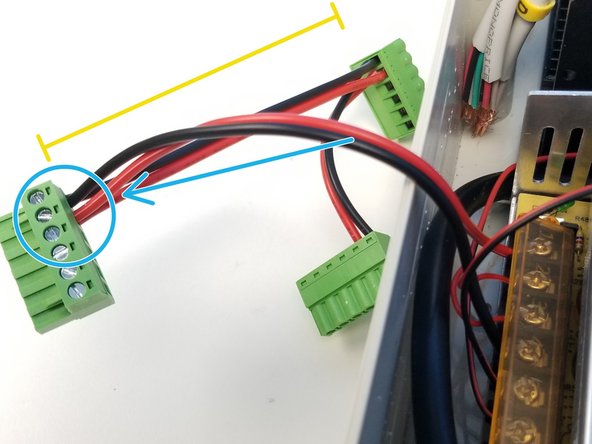

Use the shorter 18AWG 2-pin power cable and attach it to big 6-pin screw terminal

-

Attach the other end of the shorter 18AWG cable and one end of the longer 18AWG to another 6-pin screw terminal

-

Now repeat the second step with the longer 18AWG cable and the 18AWG cable that's already in the PSU with the last 6-pin screw terminal

-

-

-

Start with M0 cables from the GX16 Aviation Plug and the screw terminal that's directly connected to PSU.

-

Start with Black, Green, Red, White

-

Repeat the same process for M1 and M2 as shown in the second picture.

-

-

-

Optional Step:

-

Use the Ferrule Crimp Pins to connect 22AWG power wires as shown in the first picture, do this for cable from PSU as well.

-

The same color code as bigger drivers applies to DM320T, just repeat step 30 with M3-5 Motor Wires

-

-

-

Congratulation! you've successfully finished assembling the Electronic Case! Go You!

-

Cancel: I did not complete this guide.

One other person completed this guide.

![[3D] Electronic Case Package](https://d3t0tbmlie281e.cloudfront.net/igi/mcr/cbVbsoyjK53cHYlG.medium)

![2-Wire Power Cable 18AWG - [160mm]](https://d3t0tbmlie281e.cloudfront.net/igi/mcr/xtinC5UEy3oLGYLs.medium)