-

-

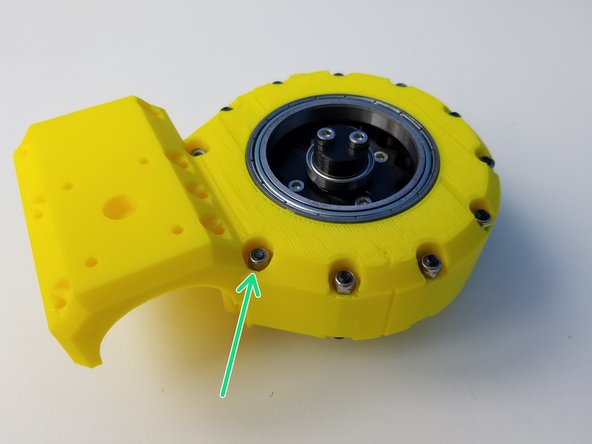

[3D] - Package #3

-

Alan Keys

-

Socket Head Driver - 5.5mm

-

Plier [Opt.]

-

-

-

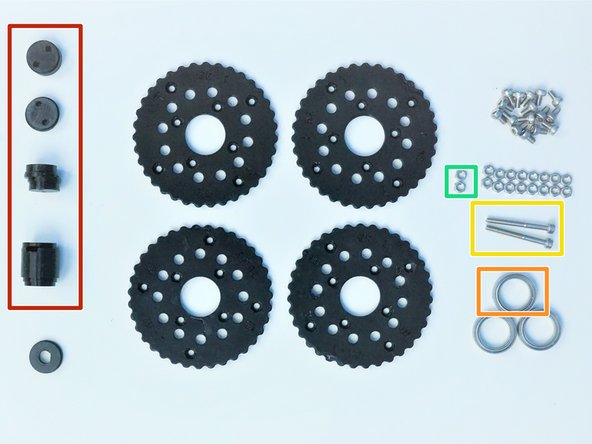

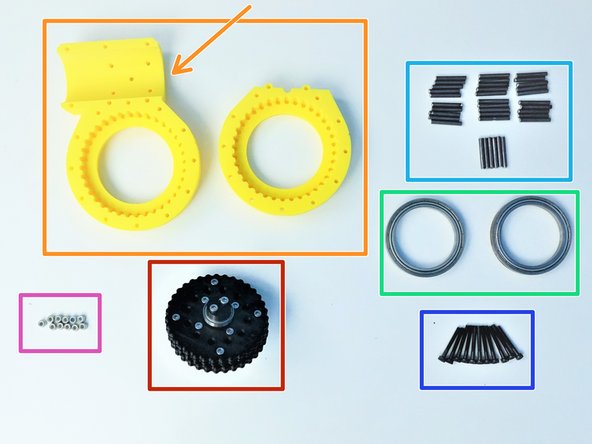

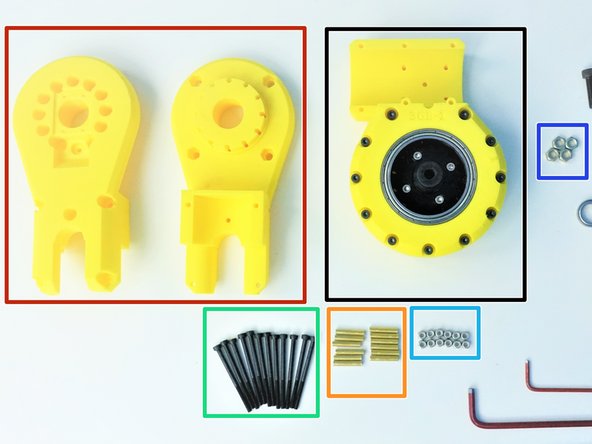

Prepare the following components:

-

[3D] - 3R Elbow GB Rotors

-

6702 Bearings [15x21x4mm] (x2)

-

M3x5mm Screws (x16)

-

M3 Hex Nuts (x16)

-

NOTE:

-

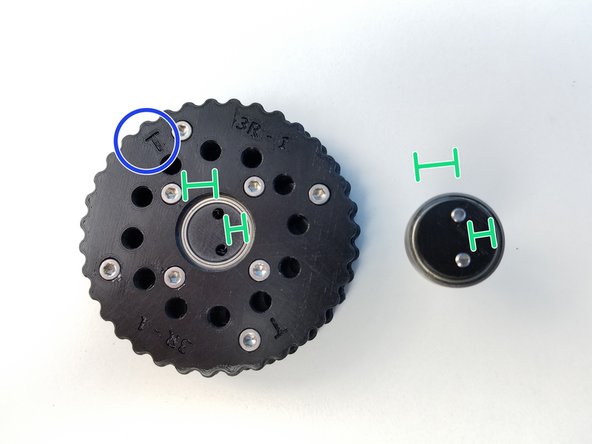

Elbow Gearbox Rotor consist of 4 similar looking parts, Be aware of T Label and B Label

-

Also Be aware of the Nut Insert vs. Screw Head Insert

-

-

-

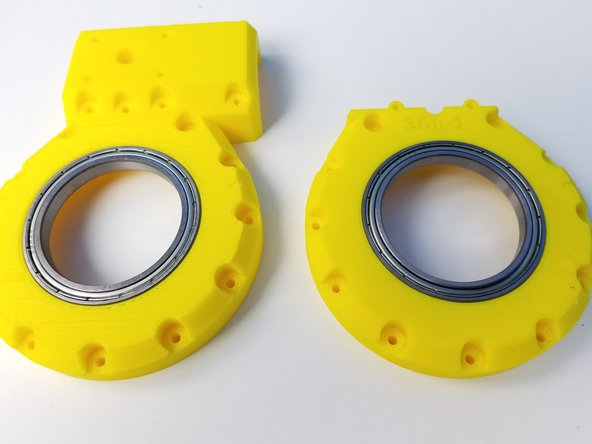

The process for "T" Rotor and "B" Rotor is the same. We will use T rotor as our guide and repeat the same process for B rotor

-

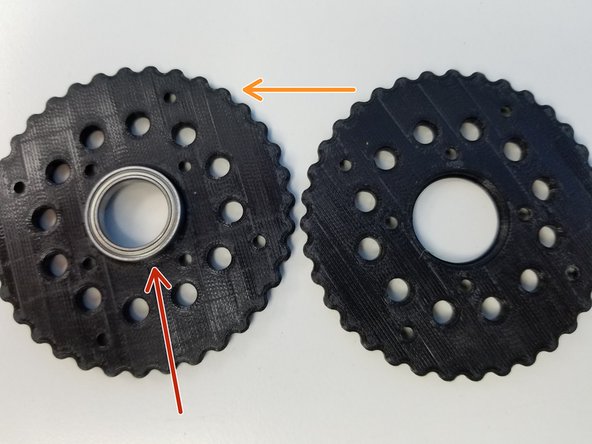

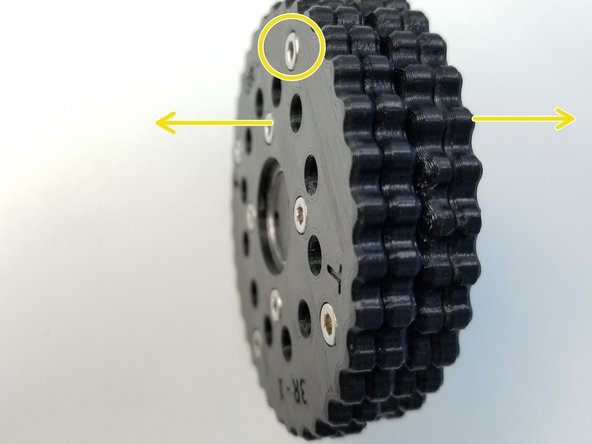

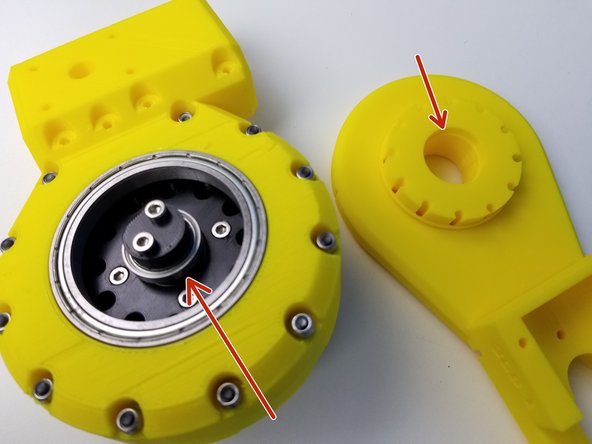

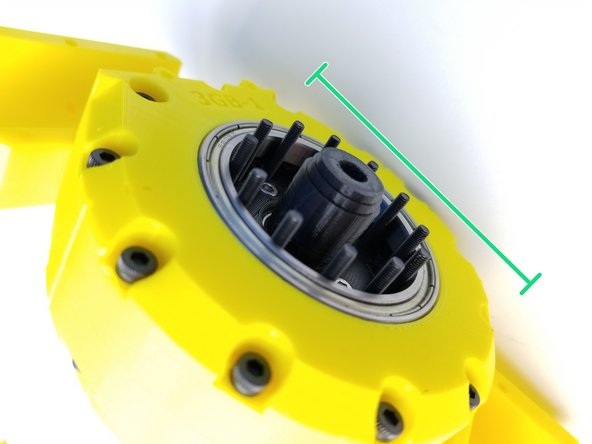

Insert 6702 Bearing on one half of the T Rotor

-

Place the other half and clamp the Bearing together

-

Make sure to align the T labels, The holes and the teeth won't line up if this isn't done correctly.

-

Insert M3x5mm Screws and Hex nuts on each half of the Rotor and tighten all the Screws.

-

Repeat the same Process for B Rotor

-

-

-

Prepare the following components:

-

Assembled Rotors

-

[3D] - 3GB Elbow Eccentric Shaft

-

6702 Bearing [15x21x4mm] (x1)

-

M3x30mm Screws (x2)

-

M3 Hex Nuts (x2)

-

-

-

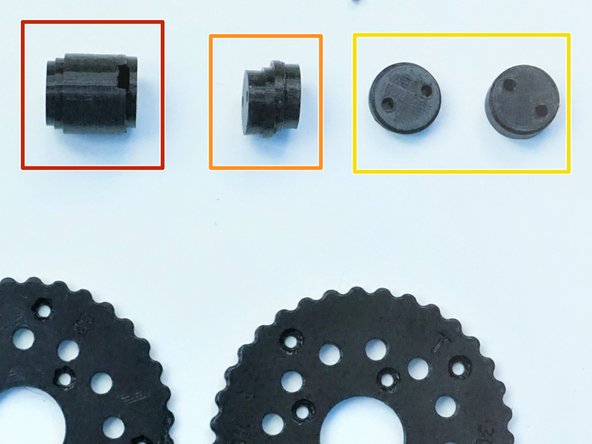

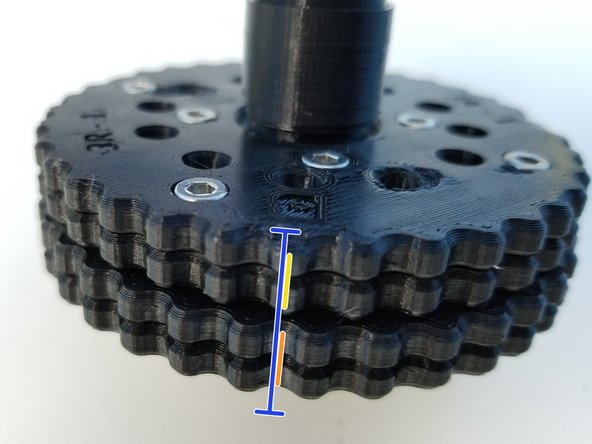

Input Shaft Consist of 4 components:

-

Motor Shaft Coupler

-

Eccentric Cam

-

Shaft Holder Cams

-

For Anti-Twist purposes, these cam holds the bearing. Thinner cam piece holds the Eccentric Cam Bearing in place as well.

-

-

-

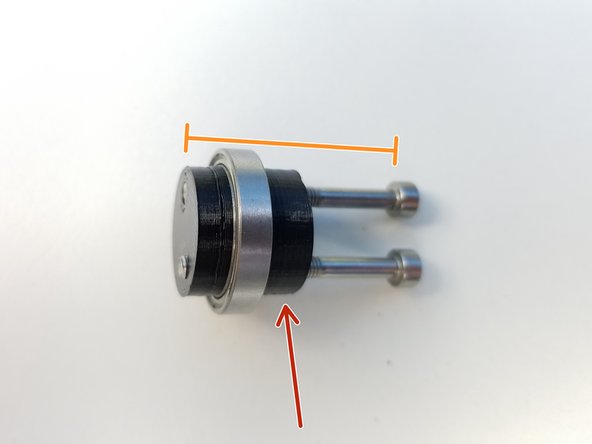

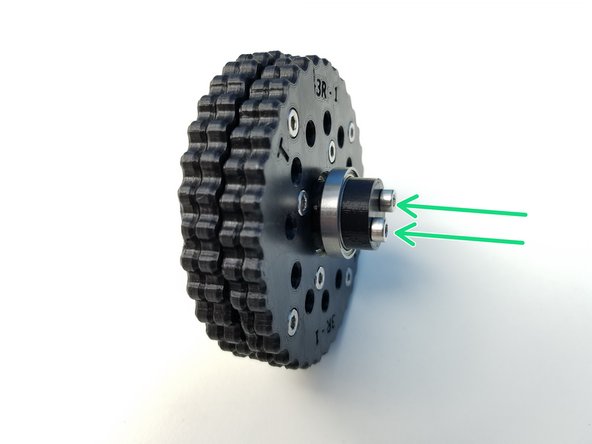

Clamp 6702 Bearing with Shaft Holder Cams using M3x30mm Screws

-

Thicker piece is the Screw Head side,

-

Only screw in until the tip of the screw is flushed with the face of the thinner piece

-

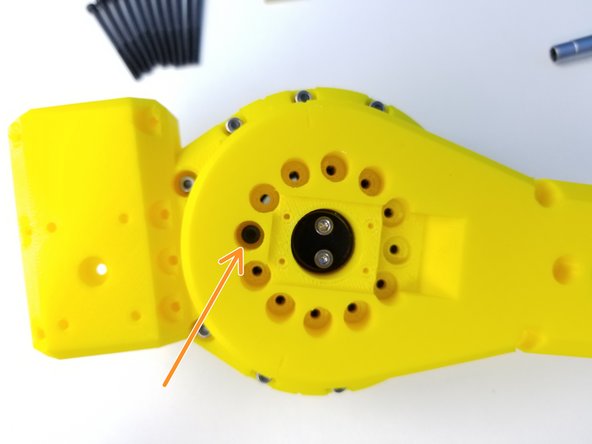

Insert both Rotors on the Eccentric Cam

-

The Screw Head side of each rotor is facing away from each other

-

Align the Eccentric Cam and Shaft Holder Cams and partially screw in the M3x30mm Screws.

-

Check that the T Rotor is facing the Shaft Holder Cam

-

-

-

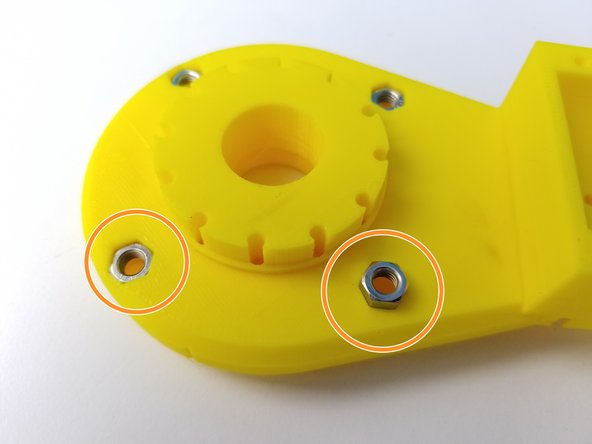

Insert M3 Hex Nuts on the side of the Motor Shaft Coupler

-

Align the Coupler offset and Eccentric Cam offset

-

Make sure the B Rotor and its Screw Head side facing the Coupler

-

Screw in the rest and Tighten it

-

-

-

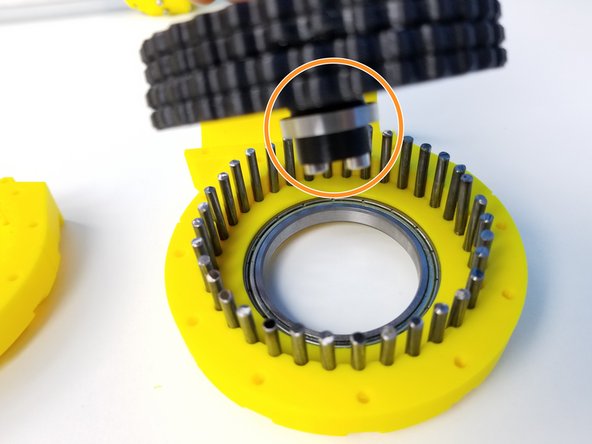

Prepare the following components:

-

Assembled Input Shaft and Rotors

-

[3D] - 3GB Elbow GB Housing Top Halves

-

NOTE that the one of the Housing Halves has extra extrusion on top, this is the Sensor Side

-

6809 Bearings [45x58x7mm] (x2)

-

Steel dowel pin - [3x24mm] (x36)

-

M3x25mm Screws (x11)

-

M3 Nylock Nuts (x11)

-

-

-

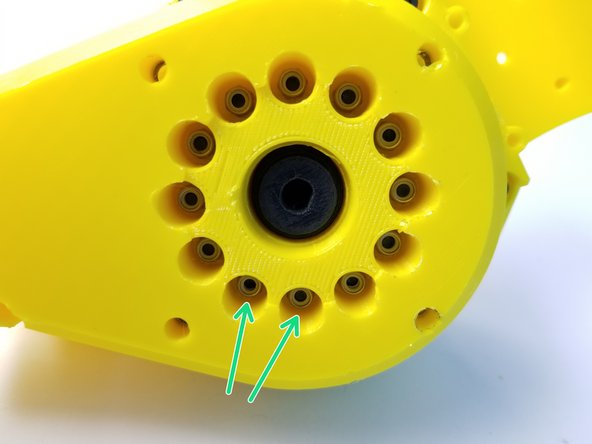

Insert 6809 Bearings on the Housings

-

Insert all 36 Steel Pins on the Sensor Side Half of the Housing

-

-

-

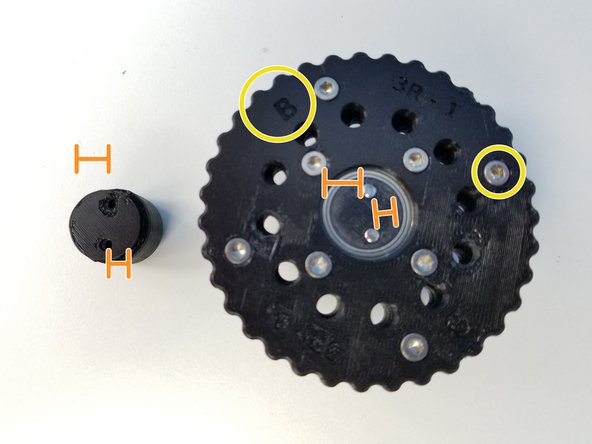

Alignment of the rotor is critical for these gearbox to work.

-

Notice that there are 2 "T" Labels on the T rotor, and same with B rotor with "B" Labels

-

One "T" is on the Tooth and the other "T" is in between 2 Teeth, This is also the same with B rotor

-

Make a Sharpie Mark in between the teeth of "T" Rotor Where the "T" is Labeled

-

For B Rotor, Make a sharpie mark on the tooth where the "B" is Labeled.

-

The Correct Alignment will look something like the Third Picture

-

-

-

Once the Rotor is Properly aligned, all 12 inner holes will have the same space between them when looking directly above it

-

Carefully insert the Rotor while maintaining this position on the Housing with the pins.

-

Make sure the Shaft Holder Cam side of the shaft is going in first

-

Press the second half of the gearbox into place.

-

Verify that you can manually turn the eccentric shaft in the center and that the rotors smoothly turn inside the housing. Tight printing and misaligned rotors can cause the gearbox to jam.

-

Clamp the other half of the Housing using M3x25mm Screws and Nylock Nuts

-

Secure tightly using the 5.5mm Socket Driver to hold the Nuts.

-

-

-

Prepare the following components:

-

Assembled Elbow Gearbox Top

-

[3D] - 3GB Elbow GB Bottom Halves

-

Brass Tubes [3.5mmx18.5mm] (x12)

-

M3x45mm Screws (x12)

-

M3 Nylock Nuts (x12)

-

M5 Hex Nuts (x4)

-

-

-

Align the Bearing Insert of the Gearbox Bottom Sensor Side Piece to the Shaft Holder Cam Bearing of the Input Shaft

-

Insert M3x45mm Screws all the way through

-

If Screws aren't going in correctly, you will have to re do the steps, go to aligning the Rotor Step

-

Keep the Gearbox laying on its side for easier assembly

-

-

-

While keeping the Gearbox on its side, insert 3.5x18.5mm Brass Tubes on each Screws

-

Insert M5 Hex Nuts on the Motor Side of the Elbow Gearbox Bottom

-

Insert the other Half of the Elbow Gearbox Bottom and secure it with M3 Nylock Nuts using the Alan Key and Socket Driver

-

-

-

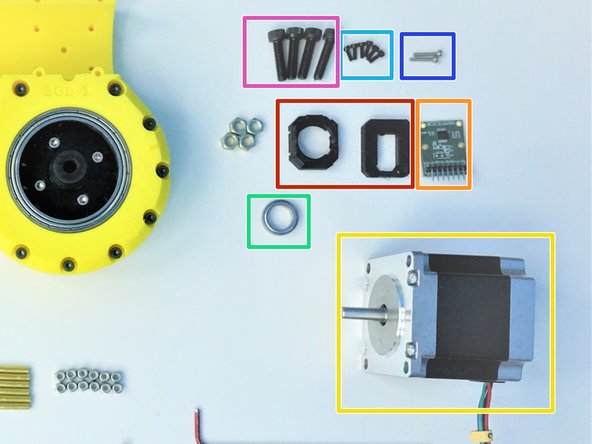

Prepare the following components:

-

[3D] - Sensor Adapter Parts

-

AS5147 Sensor [right angle headers on chip side]

-

NEMA23 56mm Motor

-

6701 Bearing [12x18x4mm] (x1)

-

M2x6mm Screws (x6)

-

M2x10mm Screws (x2)

-

M5x20mm Screws (x4)

-

-

-

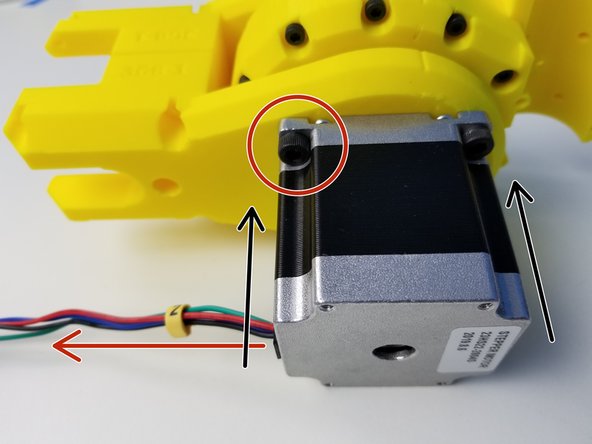

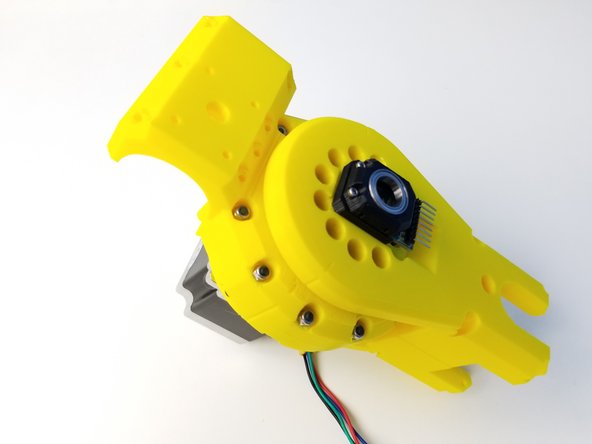

Align the D-Cut of the Motor Shaft to the Gearbox Input Shaft and insert the motor all the way through.

-

Rotate the motor body so the cable is pointing towards the bottom and secure the position using M5x20mm Screws

-

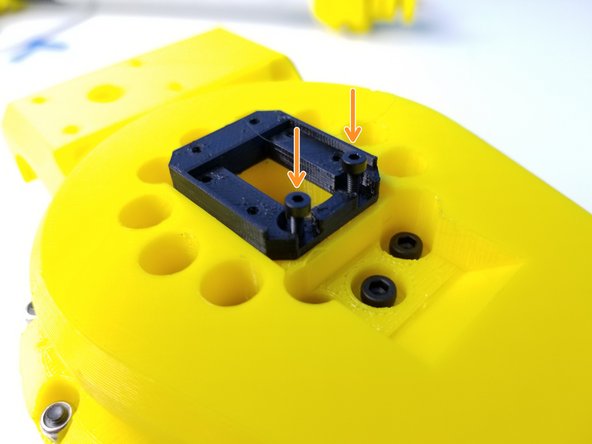

Secure the Sensor Holder using M2x6mm Screws

-

Notice the position of the Sensor holder

-

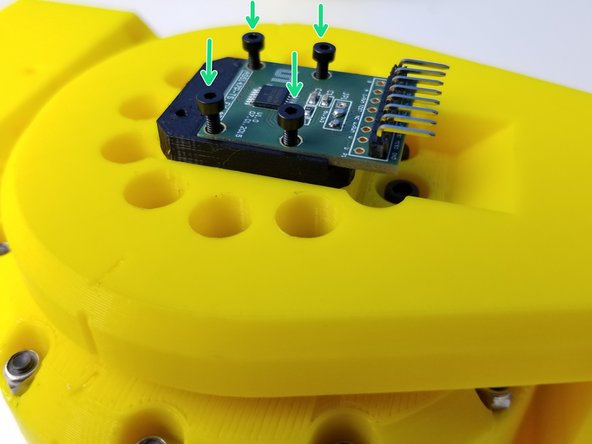

Then use the remaining M2x6mm Screws to secure the AS5147 Sensor.

-

-

-

Insert 6702 Bearing in the Sensor Bearing Holder

-

Secure the Sensor Bearing Holder part using M2x10mm screws

-

-

-

Congratulation, give yourself a high five! or the closest living thing near you!

-

Cancel: I did not complete this guide.

One other person completed this guide.

![[3D] - Package #3](https://d3t0tbmlie281e.cloudfront.net/igi/mcr/4ukeBEpy3HuIiaDh.medium)

![[3D] - 3R Elbow GB Rotors](https://d3t0tbmlie281e.cloudfront.net/igi/mcr/ygZtmqflamvDRNMi.medium)