-

-

Package #6

-

Alan Keys

-

Needle Nose Plier

-

-

-

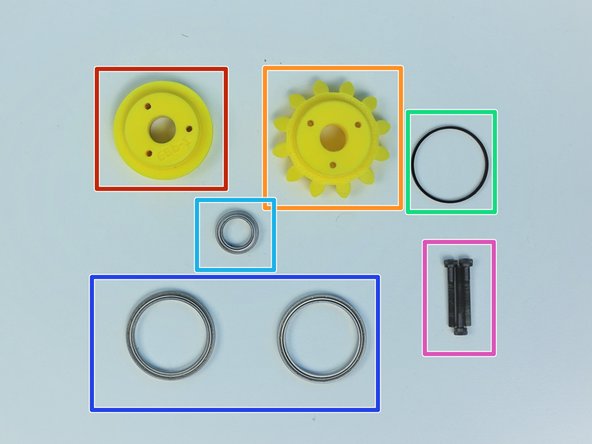

Prepare the following components:

-

[3D] - 6Da Hand GB Rotors

-

[3D] - 6Da Hand GB Eccentric Cams

-

[3D] - 6Db Hand GB Bevel Gear

-

Brass Tube [5/16' x 19.5mm]

-

6701 Bearing [12x18x4mm] (x4)

-

M3x4mm SetScrew (x3)

-

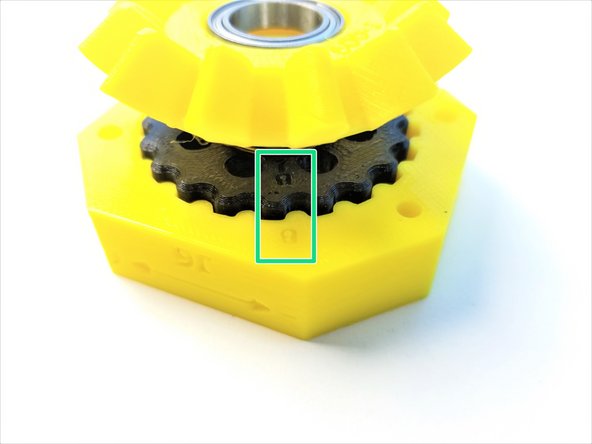

Rotors are Labelled "T" and "B" for Top and Bottom according to Eccentric Cams' Top and Bottom, Thick Piece = Bottom and Thin Piece = Top

-

-

-

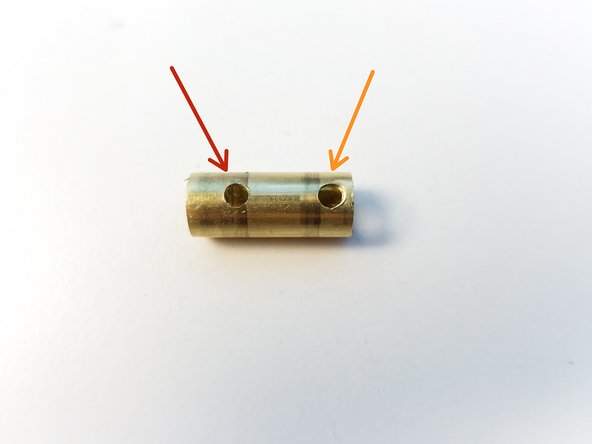

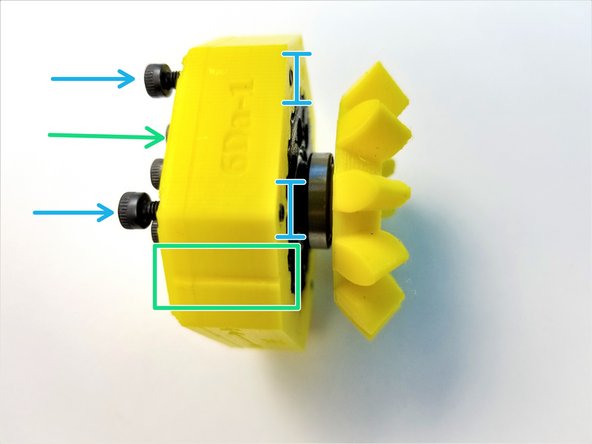

Brass Tube has one side that has 2 holes

-

Furthest away from the edge is for Bevel Gear Set Screw

-

Closest to the right edge is for Top Eccentric Cam Set Screw

-

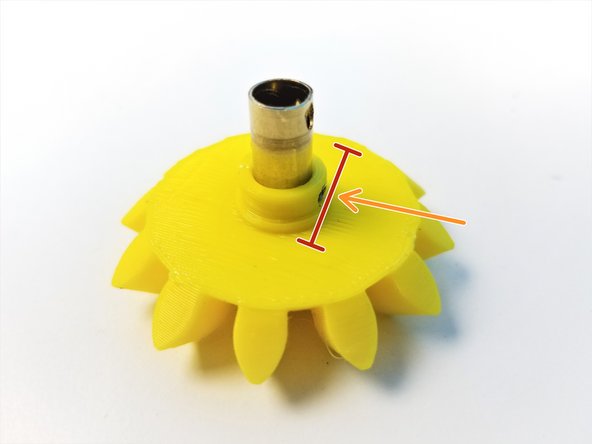

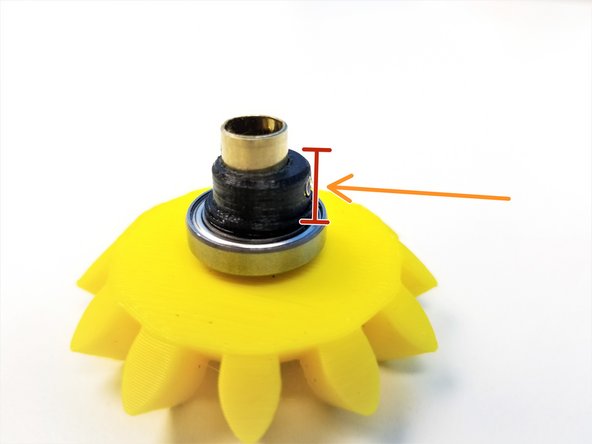

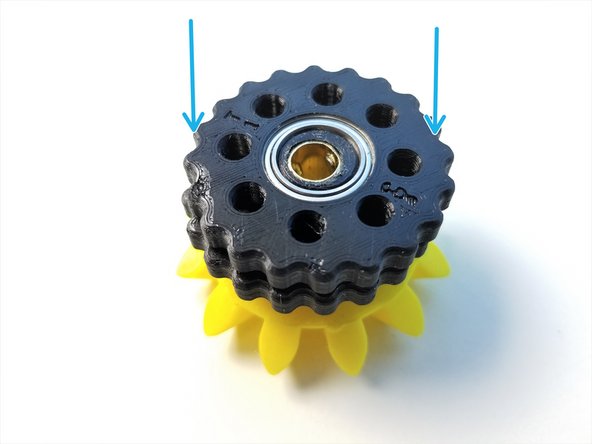

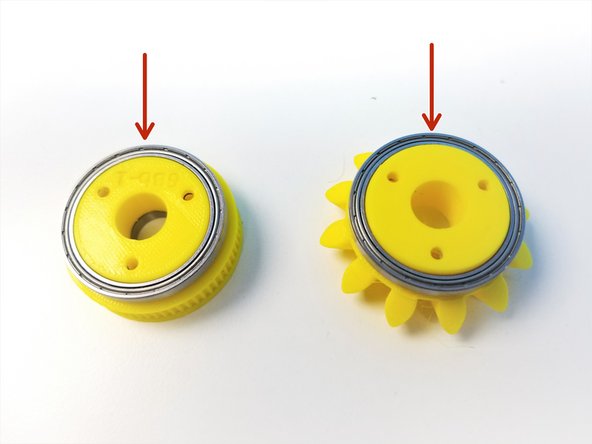

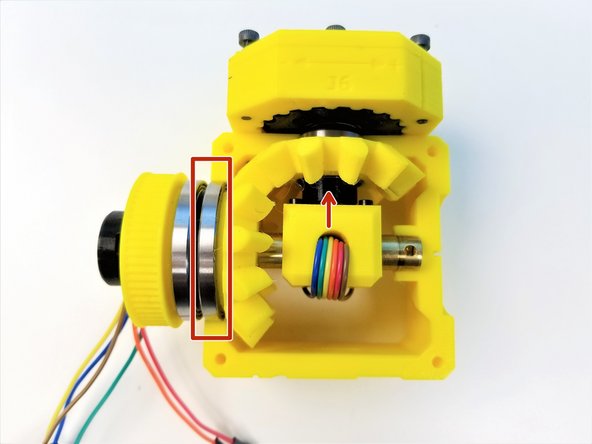

Insert 6701 Bearing in the Bevel Gear

-

-

-

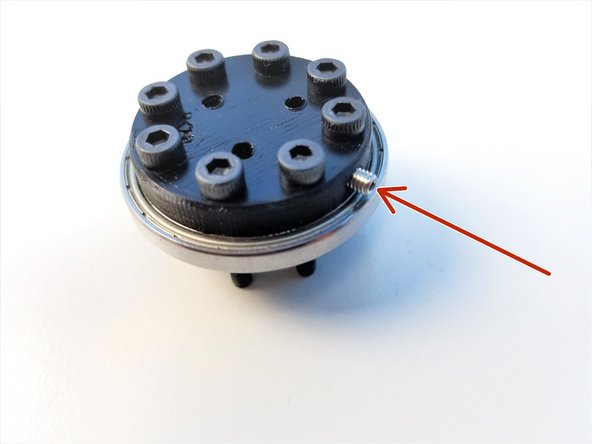

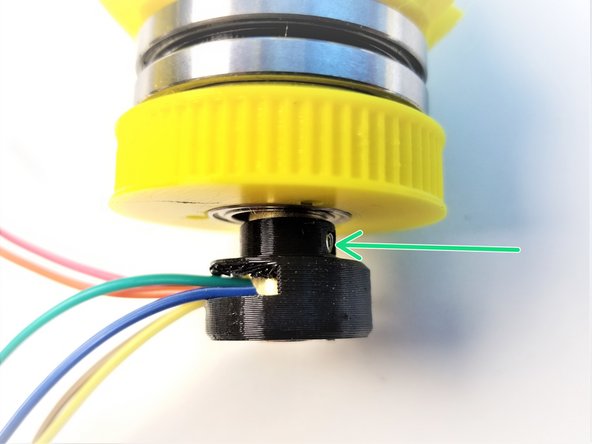

Align the Brass Tube Hole to the Bevel Gear Set Screw Hole

-

Secure the Gear using M3 Set Screw

-

Make sure the Set Screw goes in just enough for the bearing to go on, NO MORE THAN THAT

-

Slide the 6701 Bearing over the Set Screw Hole on Bevel Gear

-

-

-

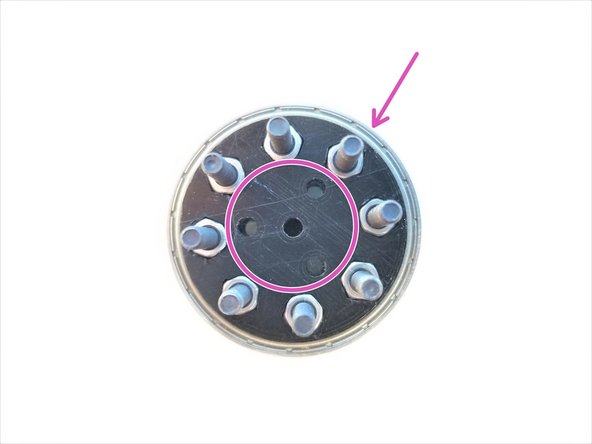

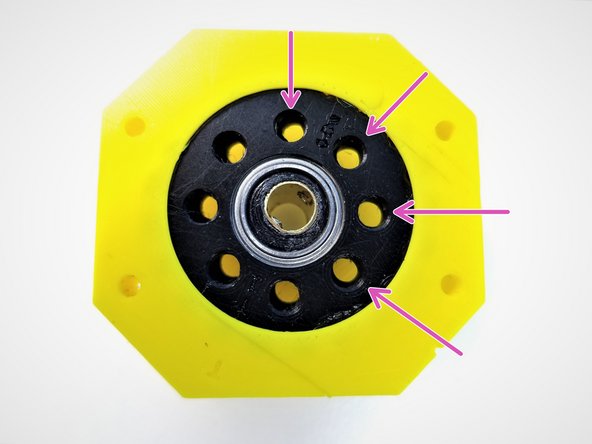

Insert 6701 Bearings into each Rotor. Make sure they are fully inserted

-

Make a sharpie mark on the side of the Rotors along the "T" and "B" label. This will help the alignment process in the future.

-

-

-

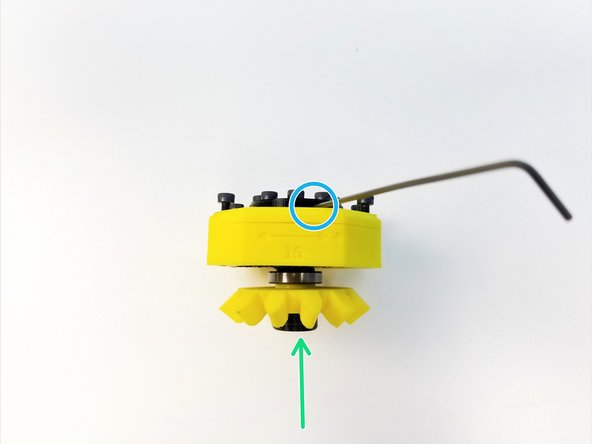

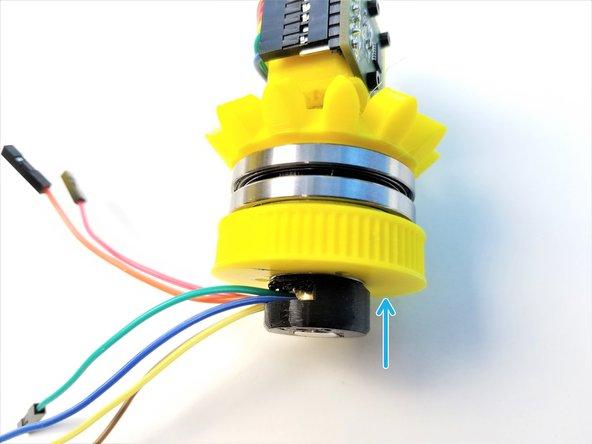

Align the Thick Eccentric Cam {Bottom} and use the M3 Set Screw to secure its location

-

Make sure the Set Screw goes in just enough for the bearing to slide over NO MORE!!

-

Place the "B" Rotor onto the eccentric cam with the "B" label facing the Bevel Gear

-

Repeat with the Thin Eccentric Cam {Top} and "T" Rotor with "T" label facing up

-

-

-

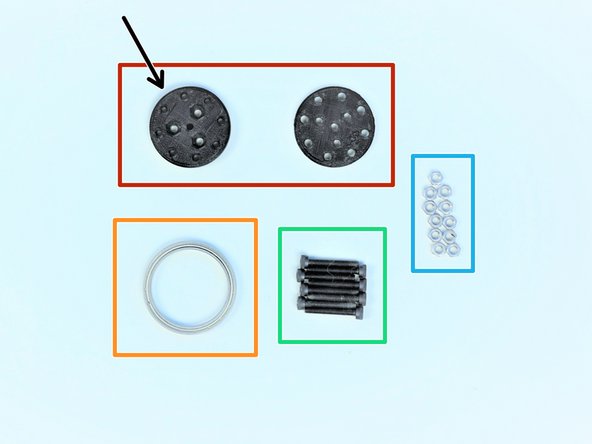

Prepare the following components:

-

[3D] - 6Da Hand GB Output Disks

-

Thicker Output Disk is considered "Top"

-

6706 Bearing [30x37x4mm] (x1)

-

M3x20mm Screws (x8)

-

M3 Hex Nuts (x11)

-

Insert M3 Hex Nuts in the nut inserts of Both Output Disks

-

Align the 3 middle holes of Top and Bottom Disks. Clamp the 6706 bearing with the Output Disks using M3x20mm Screws

-

-

-

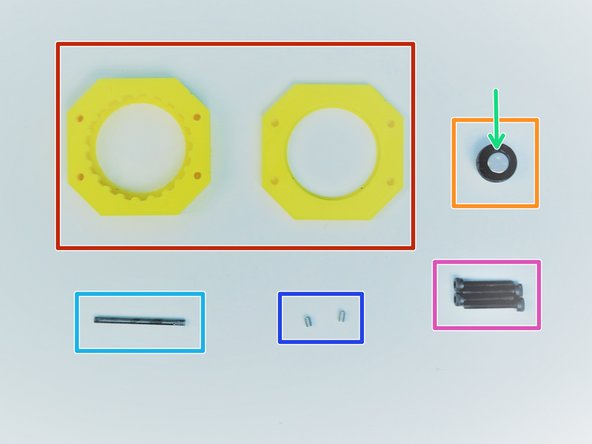

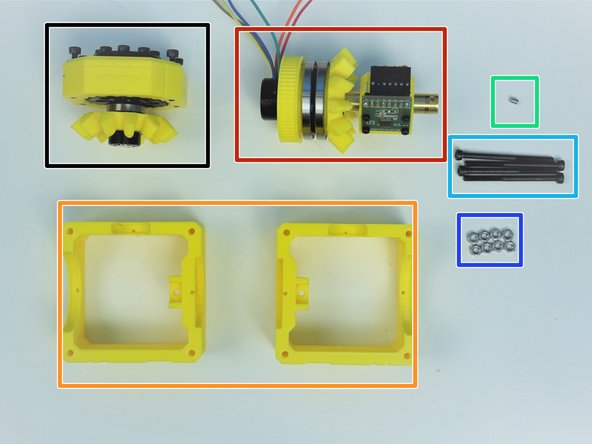

Prepare the following components:

-

[3D] - 6Da Hand GB Housing {Top & Bottom}

-

[3D] - 6Da Hand GB Magnet Holder

-

8x2.5mm Neodymium Magnet

-

M3x35mm Threaded Rod

-

Since February 2020, this is replaced with Brass Tube [1/8'x35mm]

-

M3x4mm Set Screws (x2)

-

M3x20mm Screws (x4)

-

-

-

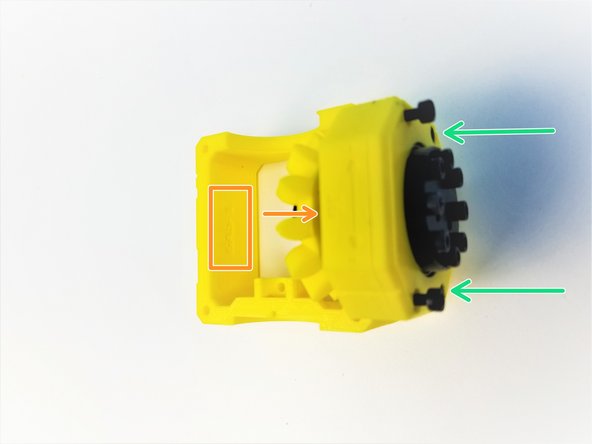

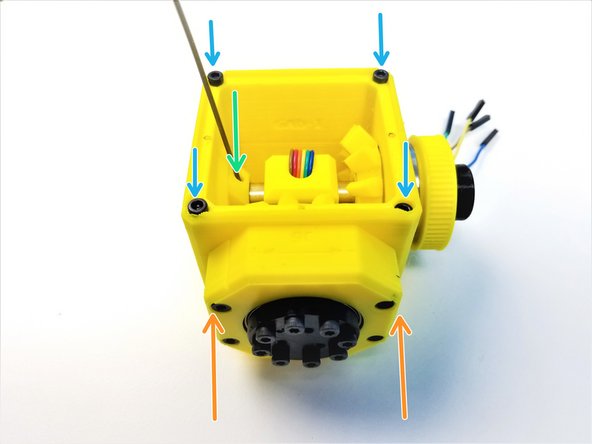

Rotor Alignment is very IMPORTANT! Follow the pictures carefully!

-

Make sure there are sharpie marks on the side of the Rotors where it lines up with "T" and "B" on the rotors

-

Align the Side Mark of "T" Rotor to the "T" on the Housing, and only insert Top Rotor into the housing.

-

Align the Side Mark of "B" Rotor to the "B" on the Housing, and insert the Bottom Rotor

-

When aligned properly all 8 holes made by 2 rotors intersecting should have equal spacing

-

-

-

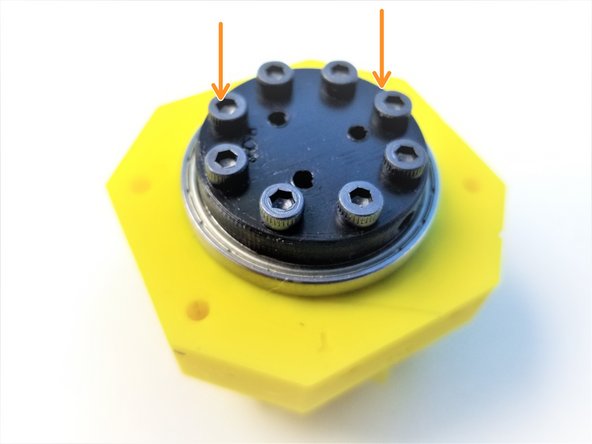

Insert M3 Set Screw on the side of the Output disk

-

Insert the Assembled Output Disk pins through the Rotors

-

Slide in the Top Housing to 6706 Bearings on the Output Disk and align the Top & Main Housings along the alignment markers

-

Secure its position using M3x20mm Screws. ONLY screw in until it's flushed to the face of the housing

-

-

-

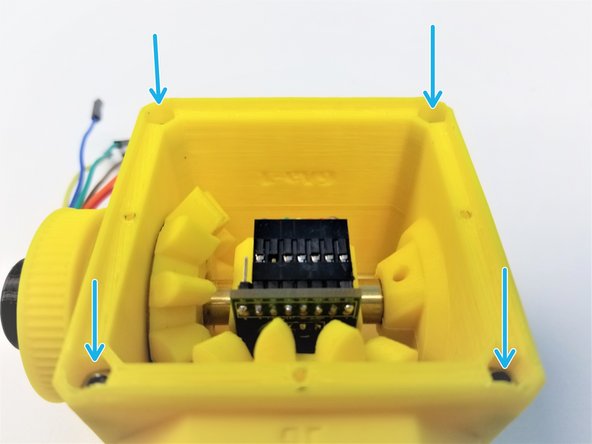

Insert the Neodymium Magnet in the Hand Sensor Magnet Holder, if you haven't yet.

-

Insert M3 Threaded Rod in the Magnet Holder. Secure the Rod using the M3 Set Screw

-

Feed the other end of the Rod to through the Input Shaft Tube all the way to Output Disk

-

Secure that end with a M3 Set Screw in the Output Disk

-

-

-

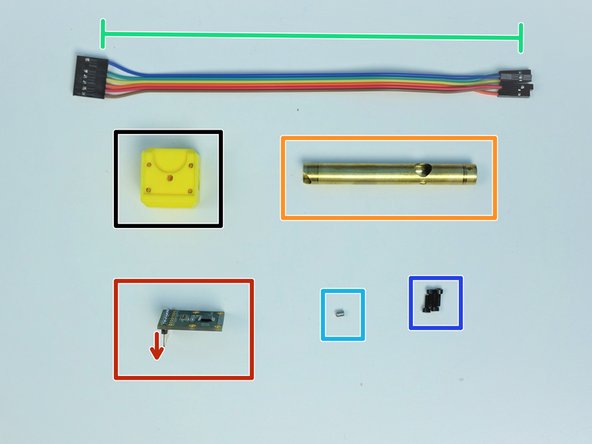

Prepare the following parts:

-

[3D] - 6PI Pulley Gear

-

[3D] - 6Ba Bevel Gear

-

[3D] - 6Bc Bearing Spacer

-

6701 Bearing [12x18x4mm] (x1)

-

6706 Bearing [30x37x4mm] (x2)

-

M3x25mm Screws (x3)

-

-

-

Slide in 6706 Bearings on the Pulley and Bevel Gear

-

Clamp the Bearing Spacer between the Pulley and the Bevel Gear using M3x25mm Screws

-

Insert the 6701 Bearing in the Pulley Gear

-

-

-

Prepare the following parts

-

[3D] - 6Ae Hand Sensor Holder

-

AS5147 Sensor {straight header on the label side}

-

Brass Tube [3/8'x76.5mm]

-

6-pin Ribbon Cable F/F - Brown to Blue {sensor 5 Hand Ext.} - [210mm]

-

M3x4mm Set Screws (x1)

-

M2x6mm Screws (x4)

-

-

-

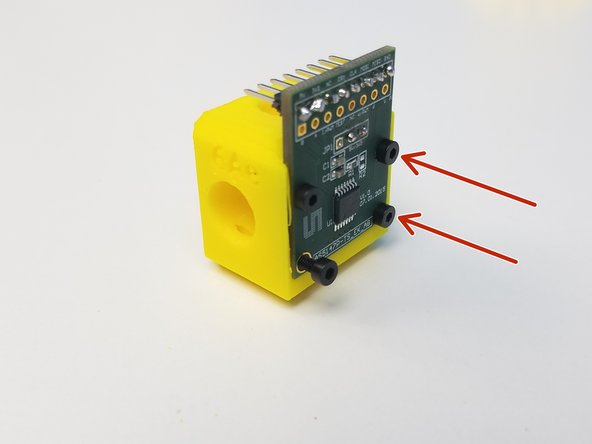

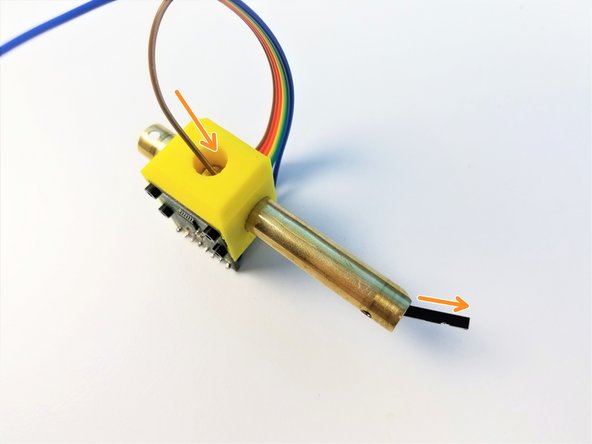

Mount the AS5147 Sensor on the Sensor Holder using the M2 Screws

-

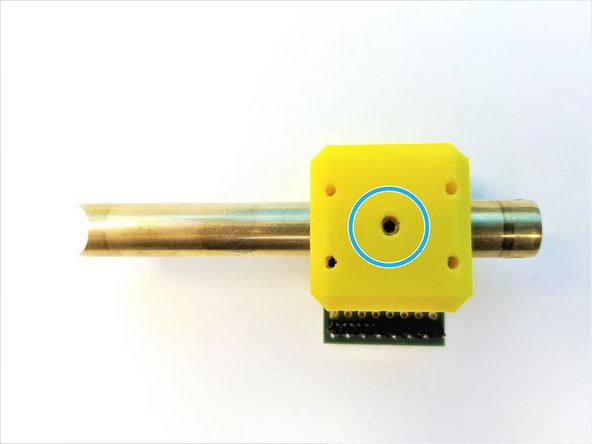

Alignment of the Brass Tube is important!!

-

Moon Cut is facing away from the Sensor Chip

-

Sensor Cable Hole is away from the Headers

-

Insert the Brass Tube through the Sensor Holder Use M3 Set Screw to secure the Sensor Holder

-

-

-

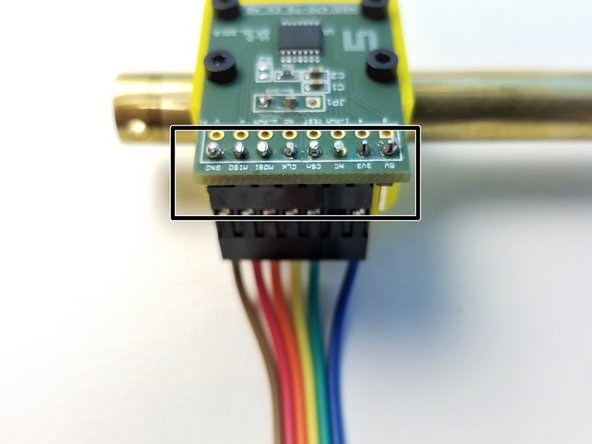

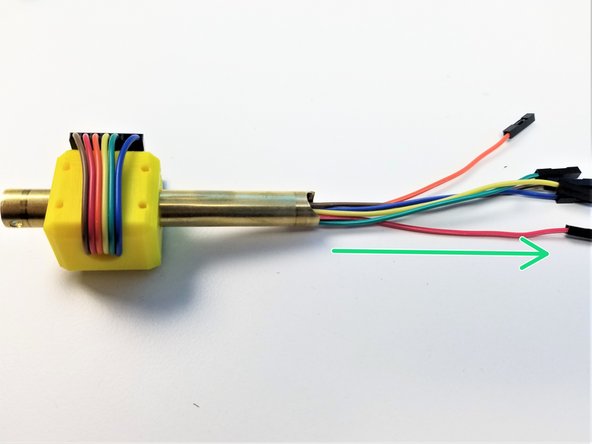

Connect the Cable to the AS5147 Sensor as shown in the picture

-

COLOR CODE MATTERS!!

-

One wire at a time, feed the jumper wires through the Brass Tube

-

Make sure the Jumper Wires comes out of the Brass Tube as far as it can. NO LOOSE Cables

-

-

-

Prepare the following components:

-

Assembled Side Bevel Gear

-

Assembled Sensor Shaft

-

[3D] - 6Mc Picasso Magnet Holder

-

8x2.5mm Neodymium Magnet (x1)

-

M3x4mm Set Screw (x1)

-

-

-

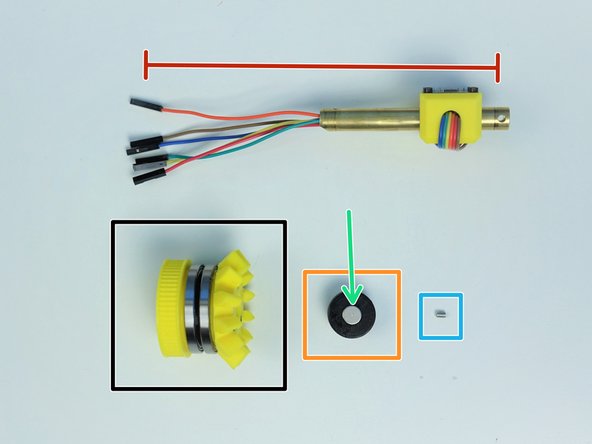

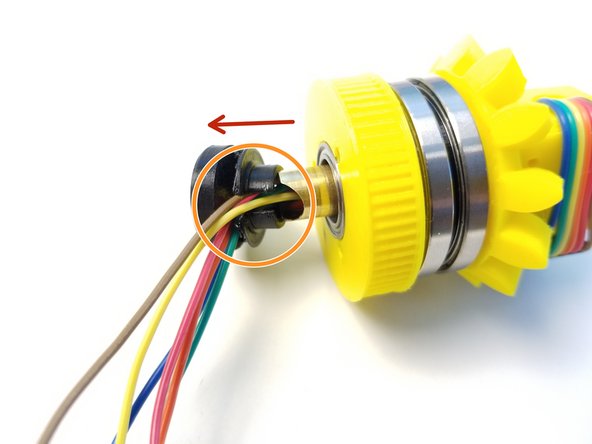

Insert the the cable end of the Brass Tube {Sensor Shaft} through the Assembled Side Bevel Gear

-

Insert Picasso Magnet Holder on the Brass Tube and align the set screw holes

-

When aligned properly, "Half Moon Cut" on the Brass Tube should line up with the opening on the Magnet Holder

-

Secure the Magnet Holder using M3 Set Screw

-

Push the Magnet Holder into the 6701 Bearing that's in the Pulley Gear

-

-

-

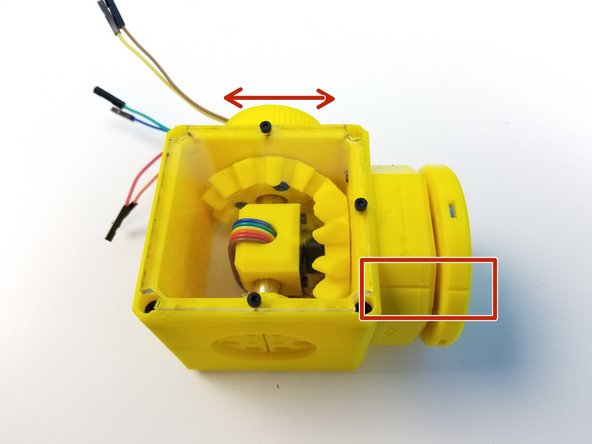

Prepare the following components:

-

Assembled Hand Gearbox

-

Assembled Side Bevel Gearbox and Sensor Holder

-

[3D] - Picasso Box {Top = 6Aa & Bottom = 6Ab}

-

M3x4mm Set Screws (x1)

-

M3x45mm Screws (x4)

-

M3 Hex Nuts (x8)

-

-

-

Insert M3 Nuts on both Picasso Box Parts

-

Insert 6701 Bearing of the Hand Gearbox into the small bearing insert of the 6Aa Picasso Box

-

Secure the Hand Gearbox using the M3x20mm Screws

-

-

-

Align the 6706 Bearing closer to Bevel Gear to the Picasso bearing insert of 6Aa Picasso

-

Hand Sensor Chip should be facing the Hand Gearbox

-

Clamp the 6Ab Picasso and secure it by tightening the M3x20mm Screws on the Hand Gearbox

-

Use M3 Set Screw to secure the Sensor Shaft to the Picasso Box

-

Insert M3x45mm Screws on one side and M3 Nuts on the other, to clamp the Picasso Box

-

-

-

Hold the picasso box with one hand and turn the input pulley of the Side Bevel Gearbox with the other.

-

The input pulley and the hand should turn smoothly at different ratios, with little or no play.

-

If the gearbox refuses to turn, it is very likely the 3D printed gears are too tight. Now is the time to reprint them before continuing with assembly.

-

-

-

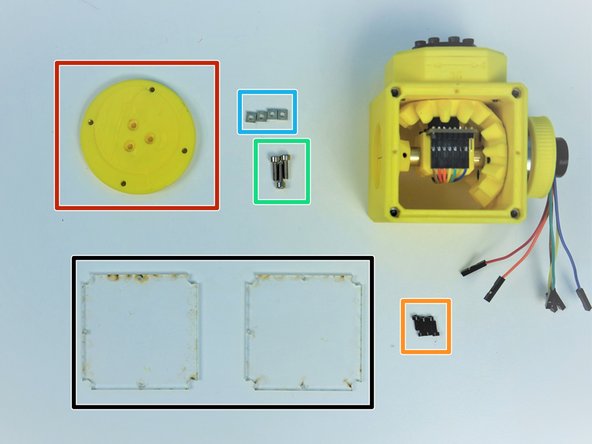

Prepare the following parts:

-

[LSR] - Acrylic Picasso Cover Plates (x2)

-

[3D] - 6Da Hand Face

-

M2x6mm Screws (x6)

-

M3x10mm Screws (x3)

-

M3 Square Nuts (x4)

-

Screw the Acrylic Plates to Top AND Bottom of Picasso Box with M2 Screws

-

-

-

Insert M3 Square Nuts on the side of the Hand Face

-

Align the Screw Hole on the ++Hand Gearbox Output and Hand Face++

-

One of three holes are in between the Screw Head

-

Secure the Face to the Output Disk using M3x10mm Screws

-

-

-

Align the Hand Face to the Hand Gearbox Housing by rotating the Pulley Gear

-

Congratulation! you have your Picasso Box assembled!!!

-

![[3D] - 6Da Hand GB Rotors](https://d3t0tbmlie281e.cloudfront.net/igi/mcr/n3COSDCEKQAQoyay.medium)

![[3D] - 6Da Hand GB Output Disks](https://d3t0tbmlie281e.cloudfront.net/igi/mcr/Cet3v2ALMRJe34OT.medium)

![[LSR] - Acrylic Picasso Cover Plates (x2)](https://d3t0tbmlie281e.cloudfront.net/igi/mcr/VGwVcvnvAJBplXtL.medium)