-

-

Package #2

-

Alan Keys

-

Socket Head Driver

-

Plier [Opt.]

-

-

-

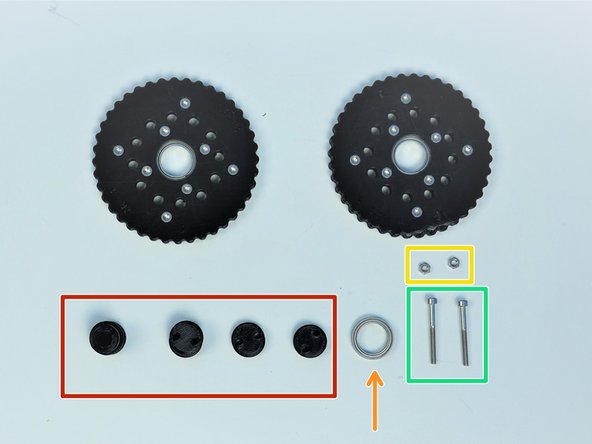

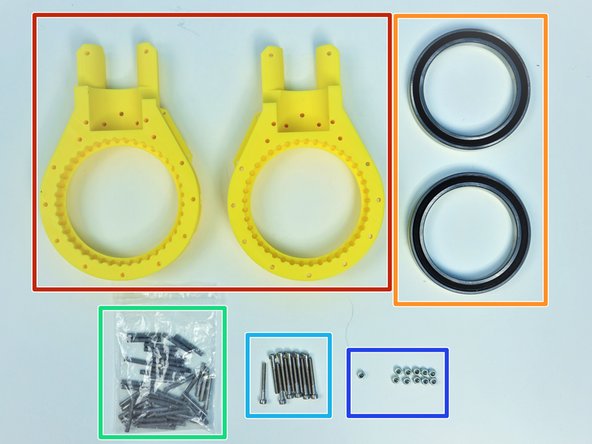

Prepare the following components:

-

[3D] - 2GB Shoulder GB Rotors

-

6702 Bearings [15x21x4mm] (x2)

-

M3x5mm Screws (x16)

-

M3 Hex Nuts (x16)

-

NOTE:

-

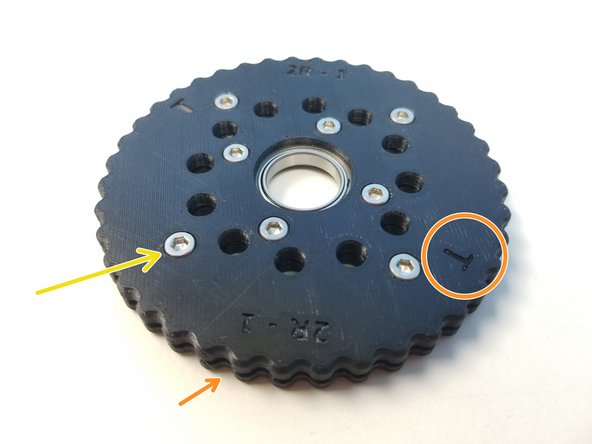

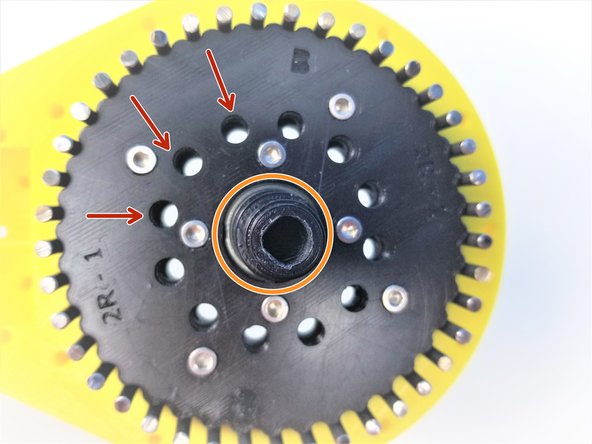

Shoulder Gearbox Rotor consist of 4 similar looking parts, Be aware of T Label and B Label

-

Also Be aware of the Nut Insert vs. Screw Head Insert

-

-

-

The process for "T" Rotor and "B" Rotor is the same. We will use T rotor as our guide and repeat the same process for B rotor

-

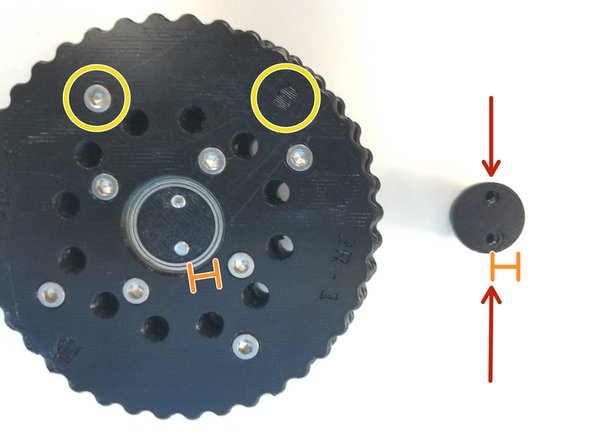

Insert 6702 Bearing on one half of the T Rotor

-

Place the other half and clamp the Bearing together

-

Make sure to align the T label, The holes and the teeth won't line up if this isn't done correctly.

-

Insert M3x5mm Screws and Hex Nuts on each half of the Rotor and tighten all the Screws.

-

Repeat the same Process for B Rotor

-

-

-

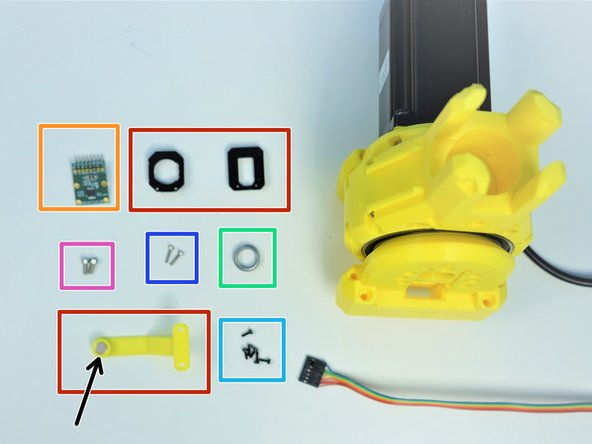

Prepare the following components:

-

Assembled Rotors

-

[3D] - 2GB Eccentric Shafts

-

6702 Bearing [15x21x4mm] (x1)

-

M3 Hex Nuts (x2)

-

M3x30mm Screws (x2)

-

-

-

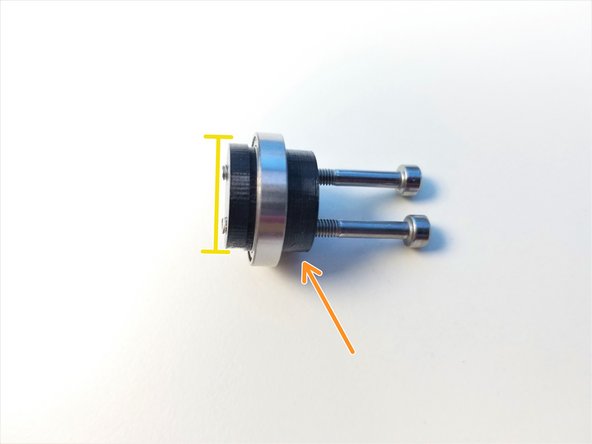

Input Shaft Consist of 4 components:

-

Motor Shaft Coupler

-

Eccentric Cam

-

Shaft Holder Cams (thin piece & thicker concentric piece)

-

Shaft Holder Cams prevent the input shaft to go off on the axis of rotation

-

-

-

Put the 6702 Bearing on the Thicker Concentric piece of the Shaft Holder

-

Notice that the thinner piece of the Shaft Holder has 2 sides, one where screw lined up to the center of the face and other which is eccentric

-

Clamp Shaft Holder Cam pieces using M3x30mm Screws

-

Thicker piece is the Screw Head side,

-

Only screw in until the tip of the screw is flushed with the face of the thinner piece

-

-

-

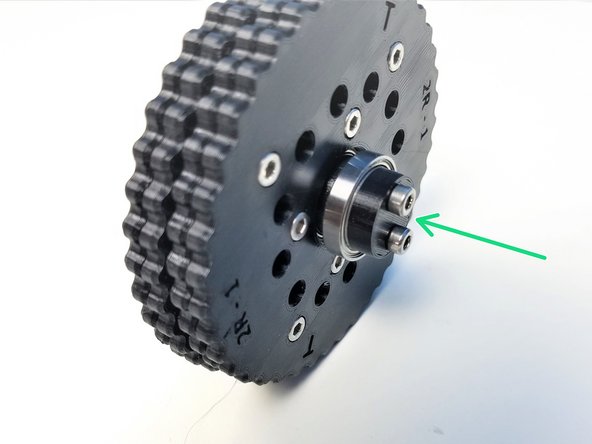

Insert Top & Bottom Rotors on the Eccentric Cam

-

The Screw Head side of each rotor is facing away from each other

-

Align the Eccentric Cam and Shaft Holder Cams and partially screw in the M3x30mm Screws.

-

Check that the T Rotor is facing the Shaft Holder Cam

-

-

-

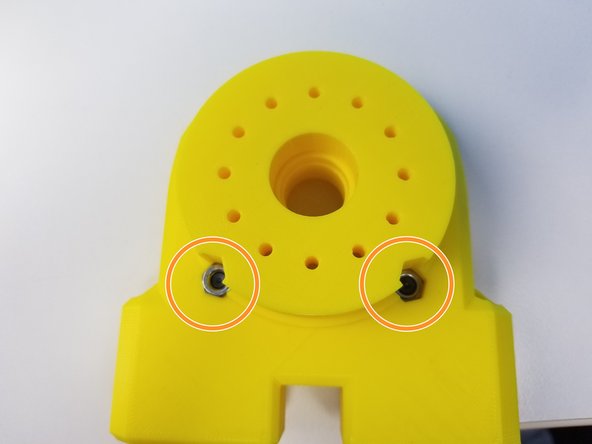

Insert M3 Hex nuts on the side of the Motor Shaft Coupler

-

Align the Coupler offset and Eccentric Cam offset

-

Make sure the B Rotor and its Screw Head side facing the Coupler

-

Screw in the rest and Tighten it

-

-

-

Prepare the following components:

-

Assembled Input Shaft and Rotors

-

[3D] - 2GB Shoulder GB Housing Top Halves

-

6813 Bearings [65x85x10mm] (x2)

-

Steel dowel pin 91595A130 - [3x24mm] (x41)

-

M3x25mm Screws (x11)

-

M3 Nylock Nuts (x11)

-

-

-

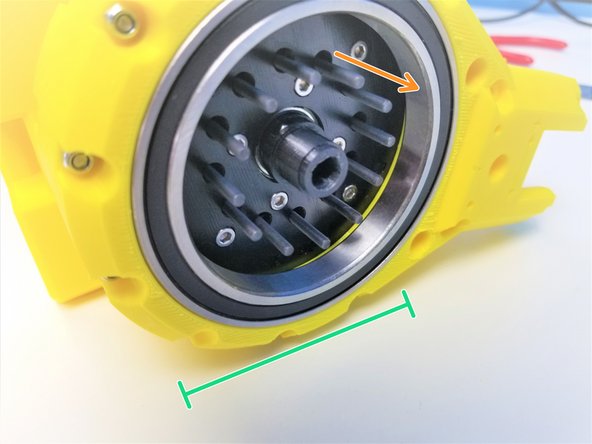

Insert 6813 Bearings on the Housing parts

-

3D-printed housing parts consist of a motor side part and a sensor side part

-

The side with Directional Label is the Motor Side

-

Insert all 41 Steel Pins on the Sensor Side Half of the Housing.

-

-

-

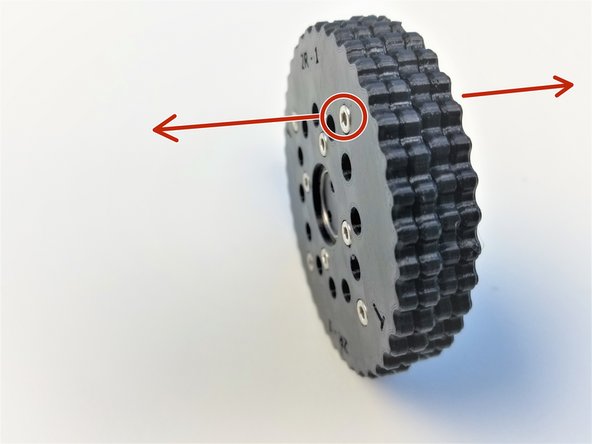

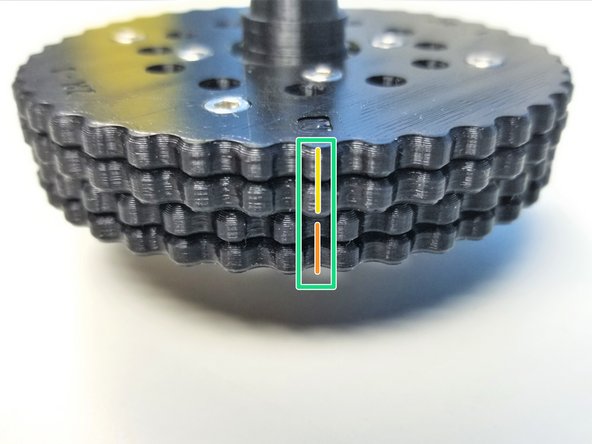

Alignment of the rotor is critical for these gearbox to work.

-

Notice that there are 2 "T" Labels on the T rotor, and same with B rotor with "B" Labels

-

T is aligned in between 2 teeth of the Top Rotor while B is aligned to the middle of a tooth

-

Make a Sharpie Mark in between the teeth of T Rotor Where the "T" is Labeled

-

For B Rotor, Make a sharpie mark on the tooth where the "B" is Labeled.

-

The Correct Alignment will look something like the Third Picture

-

-

-

Once the Rotor is Properly aligned, all 12 inner holes will have the same space between them when looking directly above it

-

The Angle of the picture taken of the aligned Rotors are a bit off.

-

Carefully insert the Rotor while maintaining this position on the Housing with the pins.

-

Make sure the Motor Shaft Adapter side of the shaft is Pointing out

-

Clamp the other half of the Housing using M3x25mm Screws and Nylock Nuts

-

Secure tightly using the 5.5mm Socket Driver to hold the Nuts.

-

-

-

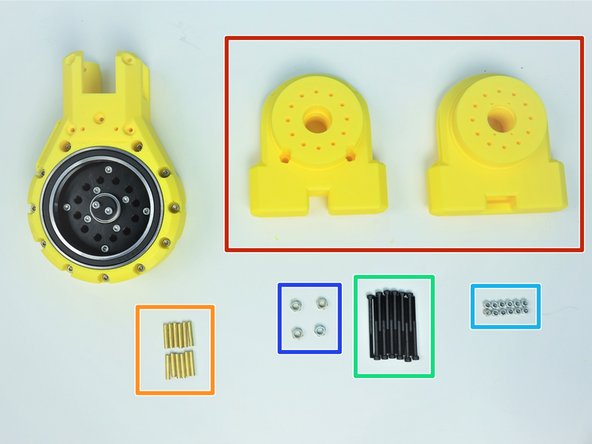

Prepare the following components:

-

Assembled Shoulder Gearbox Top

-

[3D] - 2GB Shoulder GB Bottom Halves

-

Brass Tubes [3.5x18.5mm] (x12)

-

M3x45mm Screws (x12)

-

M3 Nylock Nuts (x12)

-

M5 Hex Nuts (x4)

-

-

-

Align the Bearing Insert of the Gearbox Bottom Sensor Side Piece to the Shaft Holder Cam Bearing of the Input Shaft

-

Insert M3x45mm Screws all the way through

-

If Screws aren't going in correctly, you will have to re do the steps, go to aligning the Rotor Step

-

Keep the Gearbox laying on its side for easier assembly

-

-

-

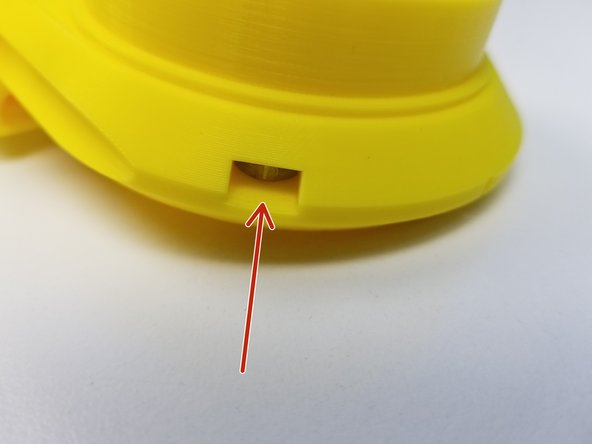

Insert M5 Hex Nuts on the side insert of the Motor Side Bottom Half

-

Insert the other two M5 Hex Nuts on the bottom inserts

-

[Opt.] if the nuts are too loose in the insert, use M5x20mm Screws (or any M5 screws) to hold it in place during assembly

-

-

-

While keeping the Gearbox on its side, insert 3.5x18.5mm Brass Tubes on each Screws

-

Insert the Motor Side of Shoulder Gearbox Bottom and secure it with M3 Nylock Nuts using the Alan Key and Socket Driver

-

-

-

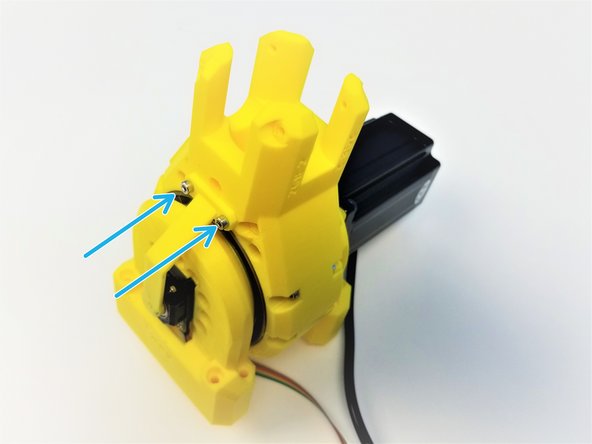

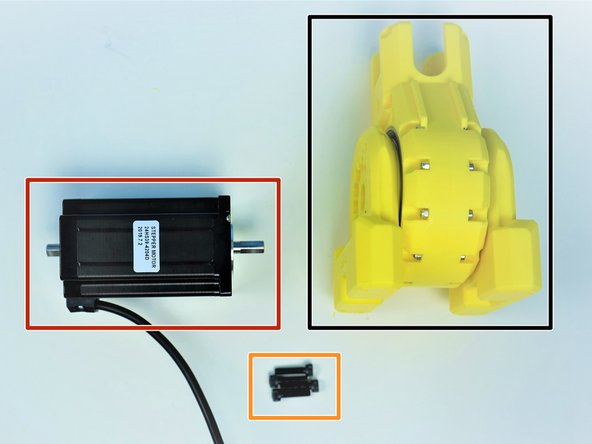

Prepare the following components:

-

Assembled Shoulder Gearbox

-

NEMA24 100mm Motor

-

M5x20mm Screws (x4)

-

Align the D-Cut of the Motor Shaft to the Gearbox Input Shaft and insert the motor all the way through.

-

Align the motor body so the cable is pointing towards the bottom and secure the position using M5x20mm Screws

-

-

-

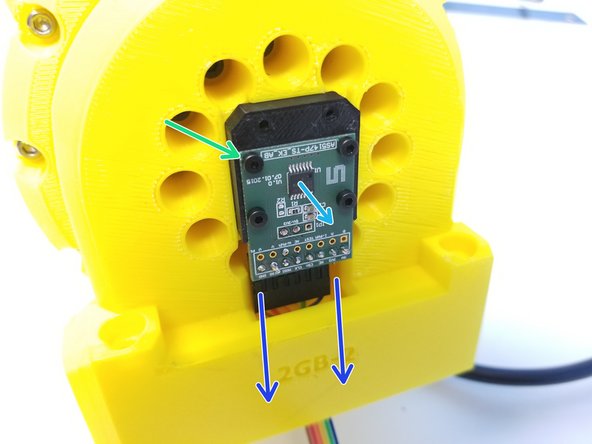

Prepare the following components:

-

[3D] - Sensor Adapter and Magnet Holder Parts

-

AS5147 Sensor [right angle headers on Label Side]

-

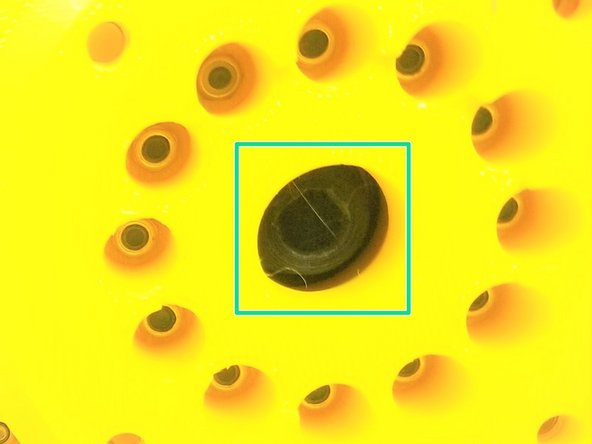

8x2.5mm Neodymium Magnet

-

6701 Bearing [12x18x4mm] (x1)

-

M2x6mm Screws (x6)

-

M2x10mm Screws (x2)

-

M3x8mm Screws (x2)

-

-

-

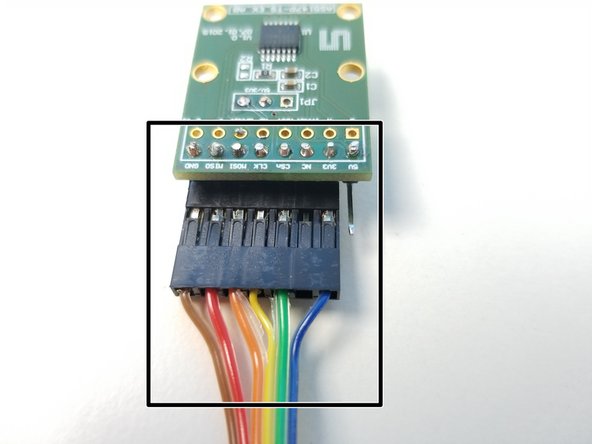

Also prepare 6-pin Ribbon Cable F/O - Brown to Blue {sensor 1 Shoulder} - [365mm]

-

There is a separate assembly guide for all sensor cable which shows the length of each as well.

-

Connect the Cable to the AS5147 Sensor as shown in the second picture

-

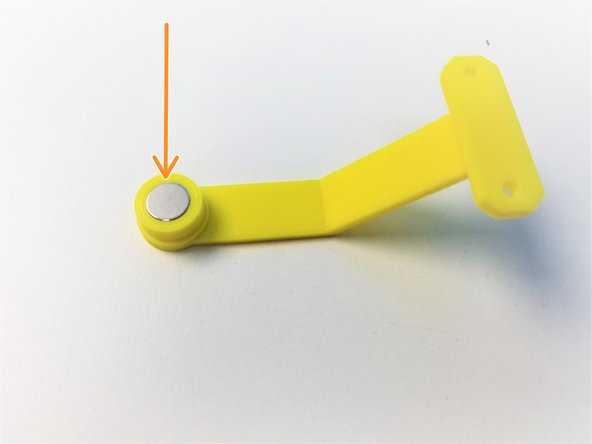

Insert the Neodymium Magnet in the Shoulder Magnet Holder

-

-

-

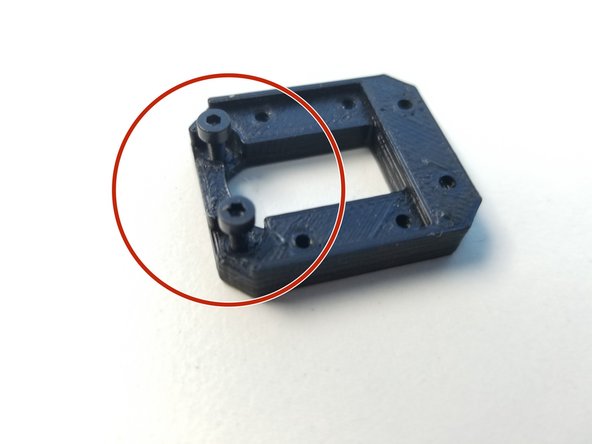

Partially screw in two M2x6mm screws in the Sensor Adapter with the screw head insert.

-

Secure the Sensor Adapter to the Sensor Side of the Gearbox with 2 screw on the bottom side of the 4 holes

-

Feed the Sensor Cable through the Tunnel

-

Then use the remaining M2x6mm Screws to Secure the Sensor to the Sensor Adapter

-

Chip is facing outward

-

-

-

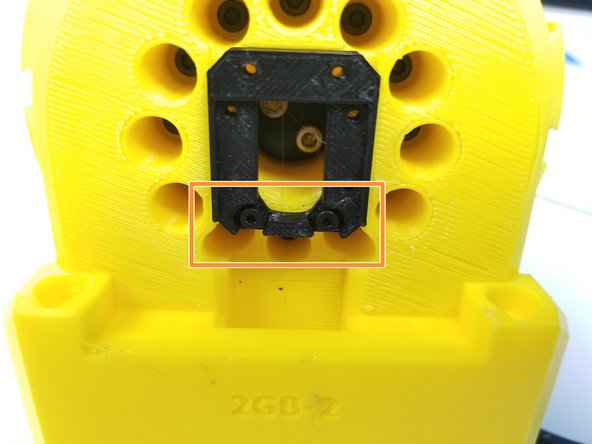

Insert 6702 bearing in the Sensor Bearing Holder part and partially screw in M2x10mm screws

-

Secure the Sensor Bearing Holder to the Sensor Adapter

-

Use M3x8mm Screws to secure the Magnet holder to the Shoulder Gearbox Top

-

-

-

Congratulation! Treat yourself with a candy break.

-

![[3D] - 2GB Shoulder GB Rotors](https://d3t0tbmlie281e.cloudfront.net/igi/mcr/AgEctOPHD6Fl5Y1C.medium)

![[Opt.] if the nuts are too loose in the insert, use M5x20mm Screws (or any M5 screws) to hold it in place during assembly](https://d3t0tbmlie281e.cloudfront.net/igi/mcr/UujeZAdTeITaFNvg.medium)

![Also prepare 6-pin Ribbon Cable F/O - Brown to Blue {sensor 1 Shoulder} - [365mm]](https://d3t0tbmlie281e.cloudfront.net/igi/mcr/PBxpKS6twaEqZbml.medium)