-

-

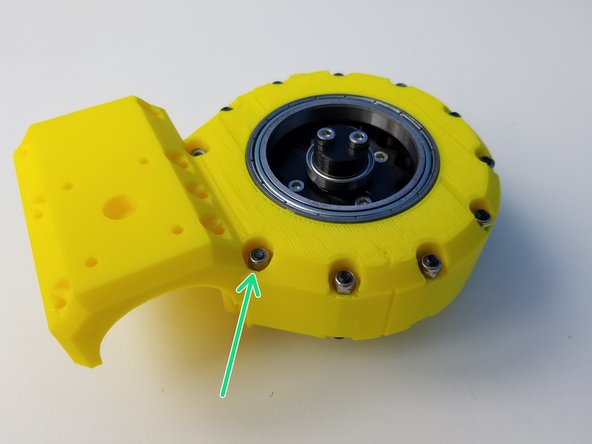

[3D] - Package #3

-

Alan Keys

-

Socket Head Driver - 5.5mm

-

Plier [Opt.]

-

-

-

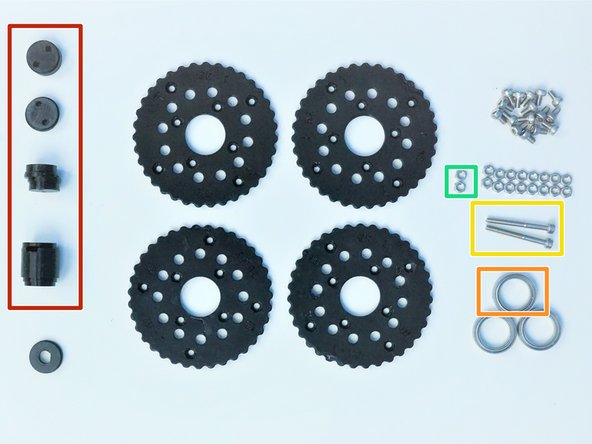

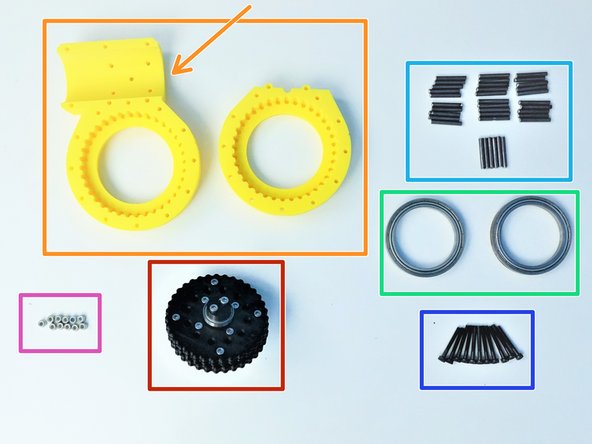

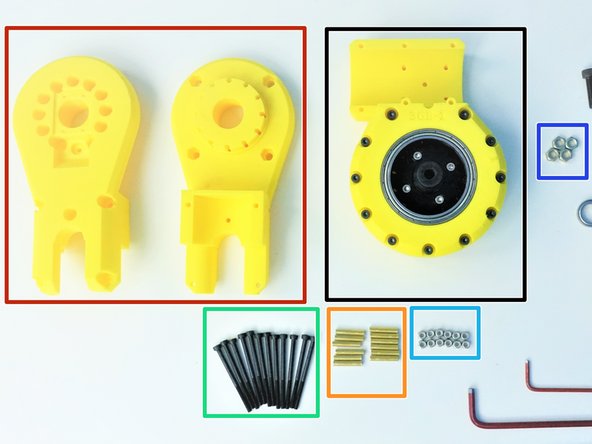

Prepare the following components:

-

[3D] - 3R Elbow GB Rotors

-

6702 Bearings [15x21x4mm] (x2)

-

M3x5mm Screws (x16)

-

M3 Hex Nuts (x16)

-

NOTE:

-

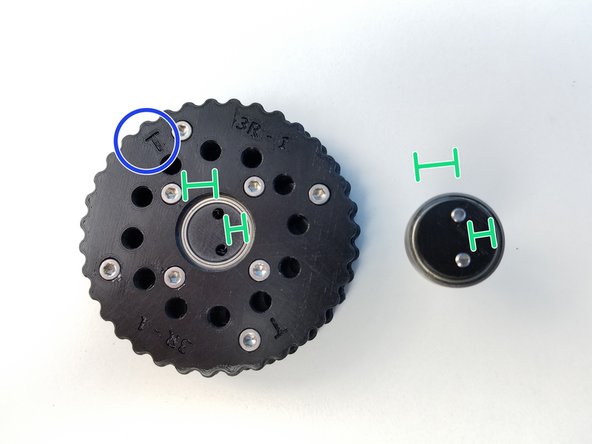

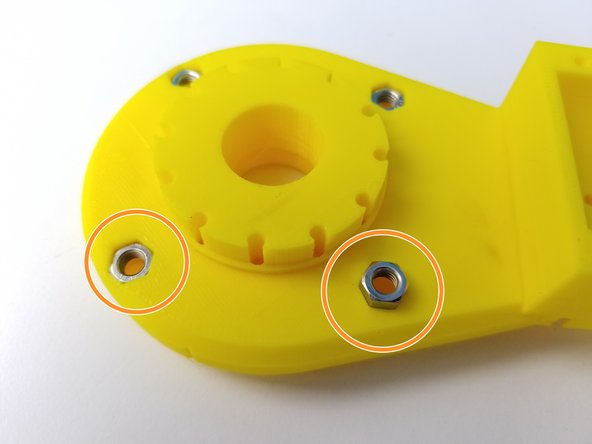

Elbow Gearbox Rotor consist of 4 similar looking parts, Be aware of T Label and B Label

-

Also Be aware of the Nut Insert vs. Screw Head Insert

-

-

-

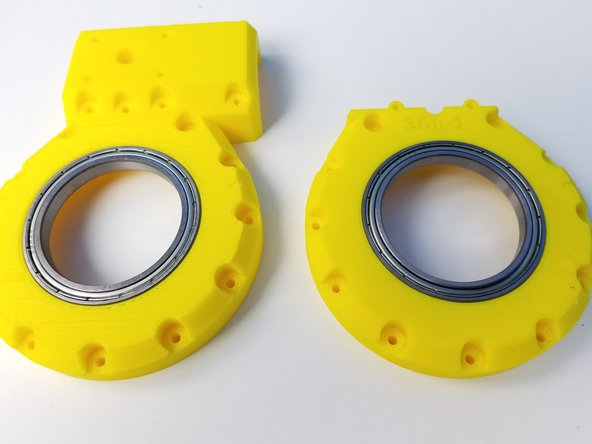

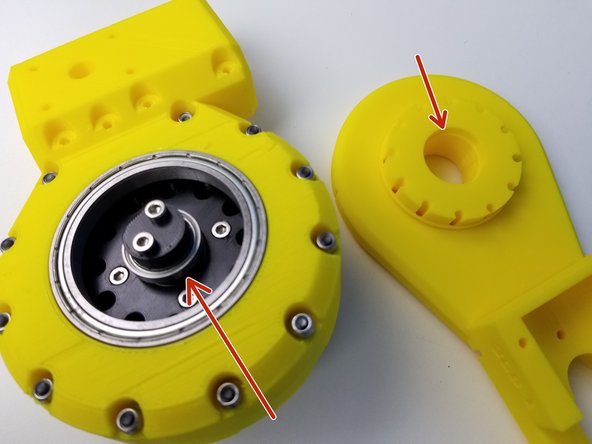

The process for "T" Rotor and "B" Rotor is the same. We will use T rotor as our guide and repeat the same process for B rotor

-

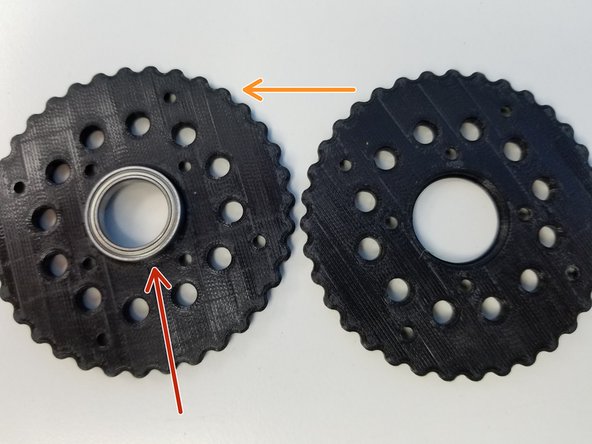

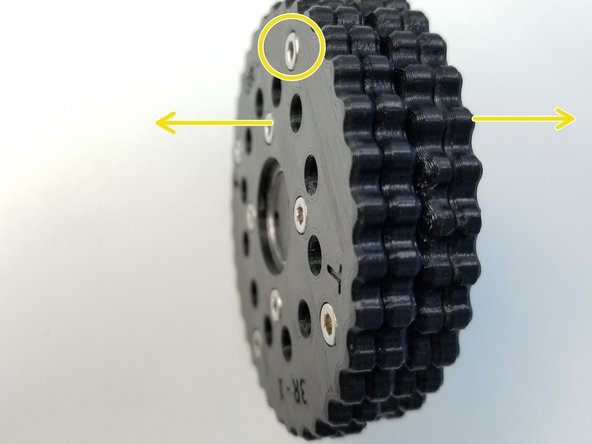

Insert 6702 Bearing on one half of the T Rotor

-

Place the other half and clamp the Bearing together

-

Make sure to align the T labels, The holes and the teeth won't line up if this isn't done correctly.

-

Insert M3x5mm Screws and Hex nuts on each half of the Rotor and tighten all the Screws.

-

Repeat the same Process for B Rotor

-

-

-

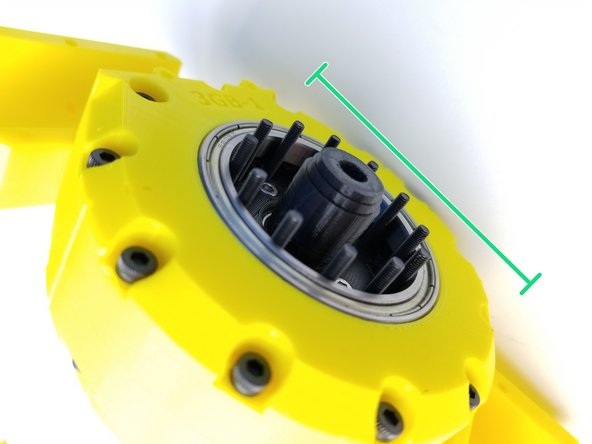

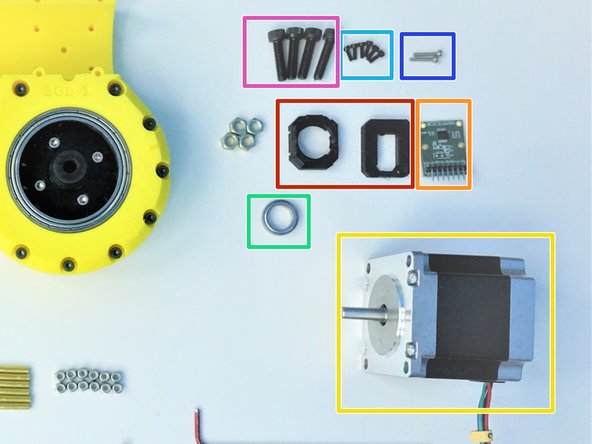

Prepare the following components:

-

Assembled Rotors

-

[3D] - 3GB Elbow Eccentric Shaft

-

6702 Bearing [15x21x4mm] (x1)

-

M3x30mm Screws (x2)

-

M3 Hex Nuts (x2)

-

-

-

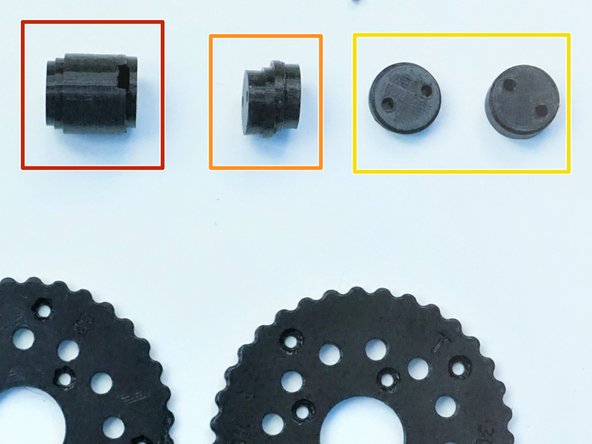

Input Shaft Consist of 4 components:

-

Motor Shaft Coupler

-

Eccentric Cam

-

Shaft Holder Cams

-

For Anti-Twist purposes, these cam holds the bearing. Thinner cam piece holds the Eccentric Cam Bearing in place as well.

-

-

-

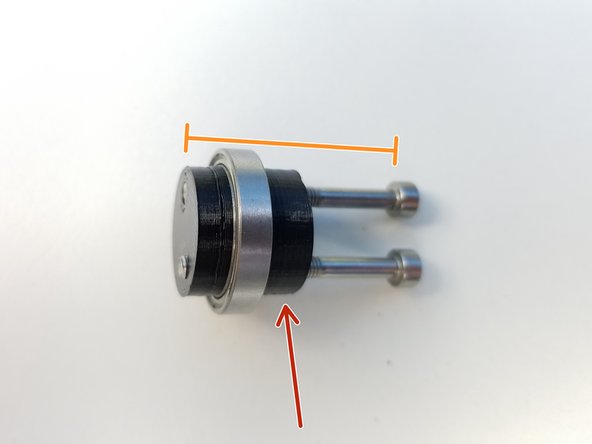

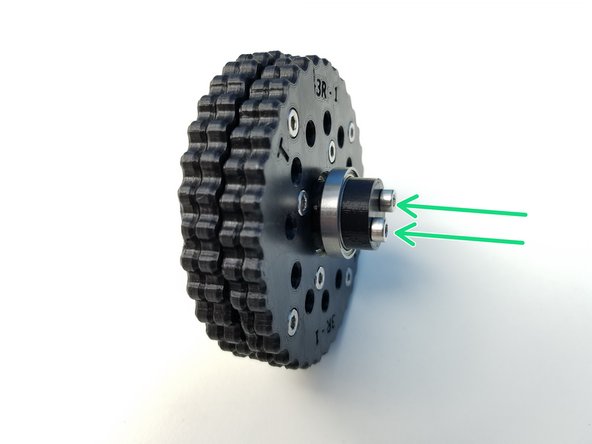

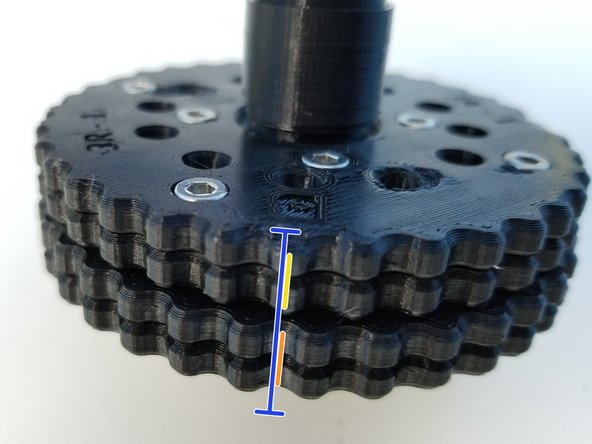

Clamp 6702 Bearing with Shaft Holder Cams using M3x30mm Screws

-

Thicker piece is the Screw Head side,

-

Only screw in until the tip of the screw is flushed with the face of the thinner piece

-

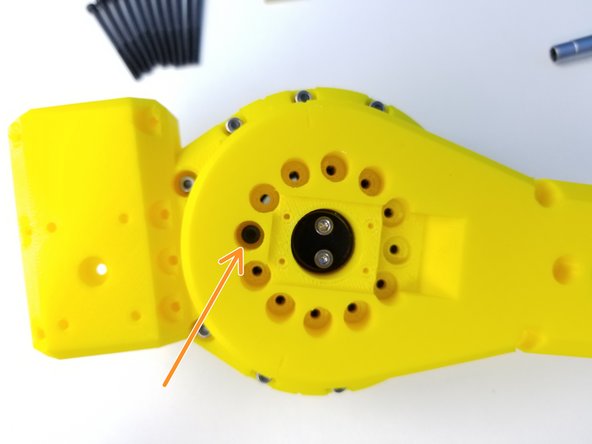

Insert both Rotors on the Eccentric Cam

-

The Screw Head side of each rotor is facing away from each other

-

Align the Eccentric Cam and Shaft Holder Cams and partially screw in the M3x30mm Screws.

-

Check that the T Rotor is facing the Shaft Holder Cam

-

-

-

Insert M3 Hex Nuts on the side of the Motor Shaft Coupler

-

Align the Coupler offset and Eccentric Cam offset

-

Make sure the B Rotor and its Screw Head side facing the Coupler

-

Screw in the rest and Tighten it

-

-

-

Prepare the following components:

-

Assembled Input Shaft and Rotors

-

[3D] - 3GB Elbow GB Housing Top Halves

-

NOTE that the one of the Housing Halves has extra extrusion on top, this is the Sensor Side

-

6809 Bearings [45x58x7mm] (x2)

-

Steel dowel pin - [3x24mm] (x36)

-

M3x25mm Screws (x11)

-

M3 Nylock Nuts (x11)

-

-

-

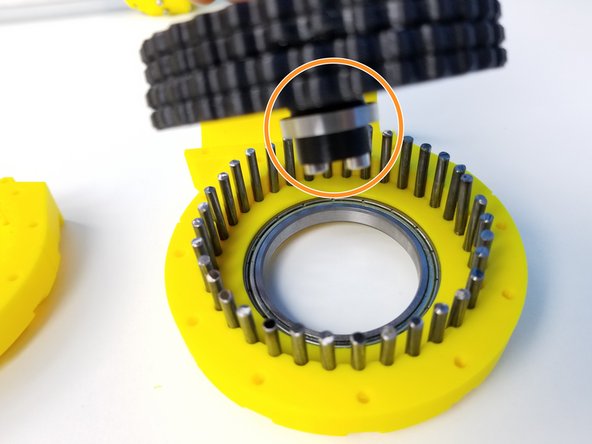

Insert 6809 Bearings on the Housings

-

Insert all 36 Steel Pins on the Sensor Side Half of the Housing

-

-

-

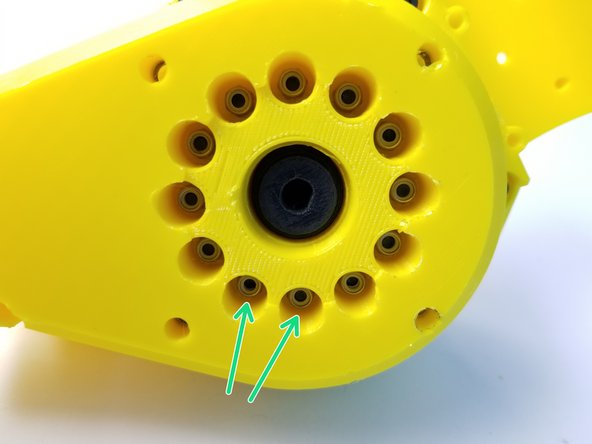

Alignment of the rotor is critical for these gearbox to work.

-

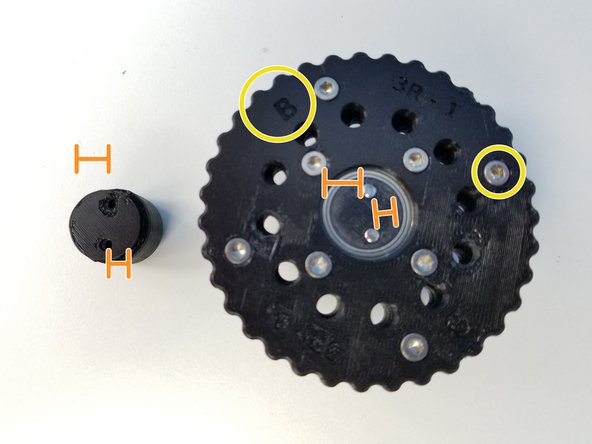

Notice that there are 2 "T" Labels on the T rotor, and same with B rotor with "B" Labels

-

One "T" is on the Tooth and the other "T" is in between 2 Teeth, This is also the same with B rotor

-

Make a Sharpie Mark in between the teeth of "T" Rotor Where the "T" is Labeled

-

For B Rotor, Make a sharpie mark on the tooth where the "B" is Labeled.

-

The Correct Alignment will look something like the Third Picture

-

-

-

Once the Rotor is Properly aligned, all 12 inner holes will have the same space between them when looking directly above it

-

Carefully insert the Rotor while maintaining this position on the Housing with the pins.

-

Make sure the Shaft Holder Cam side of the shaft is going in first

-

Clamp the other half of the Housing using M3x25mm Screws and Nylock Nuts

-

Secure tightly using the 5.5mm Socket Driver to hold the Nuts.

-

-

-

Prepare the following components:

-

Assembled Elbow Gearbox Top

-

[3D] - 3GB Elbow GB Bottom Halves

-

Brass Tubes [3.5mmx18.5mm] (x12)

-

M3x45mm Screws (x12)

-

M3 Nylock Nuts (x12)

-

M5 Hex Nuts (x4)

-

-

-

Align the Bearing Insert of the Gearbox Bottom Sensor Side Piece to the Shaft Holder Cam Bearing of the Input Shaft

-

Insert M3x45mm Screws all the way through

-

If Screws aren't going in correctly, you will have to re do the steps, go to aligning the Rotor Step

-

Keep the Gearbox laying on its side for easier assembly

-

-

-

While keeping the Gearbox on its side, insert 3.5x18.5mm Brass Tubes on each Screws

-

Insert M5 Hex Nuts on the Motor Side of the Elbow Gearbox Bottom

-

Insert the other Half of the Elbow Gearbox Bottom and secure it with M3 Nylock Nuts using the Alan Key and Socket Driver

-

-

-

Prepare the following components:

-

[3D] - Sensor Adapter Parts

-

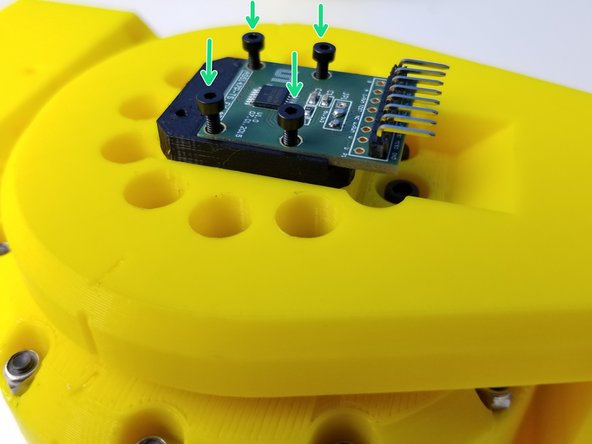

AS5147 Sensor [right angle headers on chip side]

-

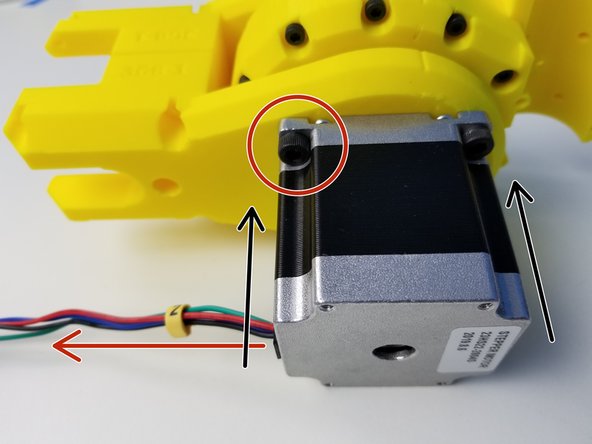

NEMA23 56mm Motor

-

6701 Bearing [12x18x4mm] (x1)

-

M2x6mm Screws (x6)

-

M2x10mm Screws (x2)

-

M5x20mm Screws (x4)

-

-

-

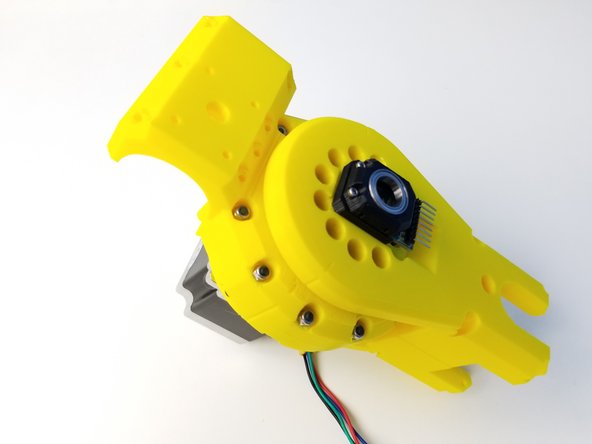

Align the D-Cut of the Motor Shaft to the Gearbox Input Shaft and insert the motor all the way through.

-

Rotate the motor body so the cable is pointing towards the bottom and secure the position using M5x20mm Screws

-

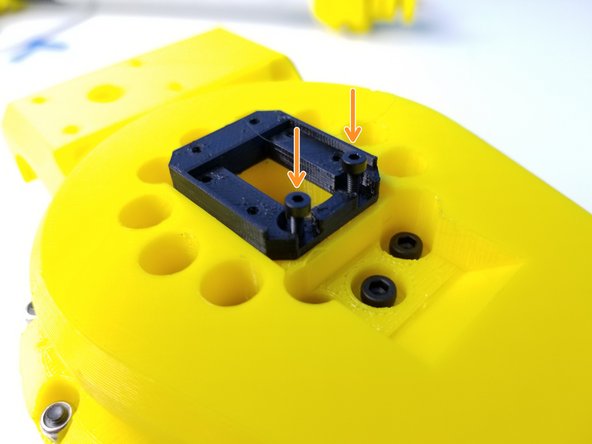

Secure the Sensor Holder using M2x6mm Screws

-

Notice the position of the Sensor holder

-

Then use the remaining M2x6mm Screws to secure the AS5147 Sensor.

-

-

-

Insert 6702 Bearing in the Sensor Bearing Holder

-

Secure the Sensor Bearing Holder part using M2x10mm screws

-

-

-

Congratulation, give yourself a high five! or the closest living thing near you!

-

![[3D] - Package #3](https://d3t0tbmlie281e.cloudfront.net/igi/mcr/4ukeBEpy3HuIiaDh.medium)

![[3D] - 3R Elbow GB Rotors](https://d3t0tbmlie281e.cloudfront.net/igi/mcr/ygZtmqflamvDRNMi.medium)