-

-

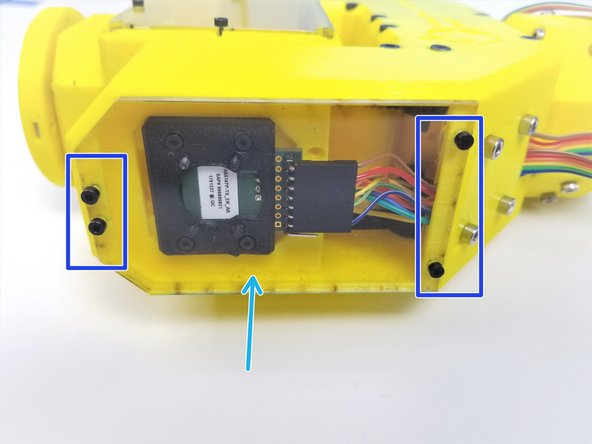

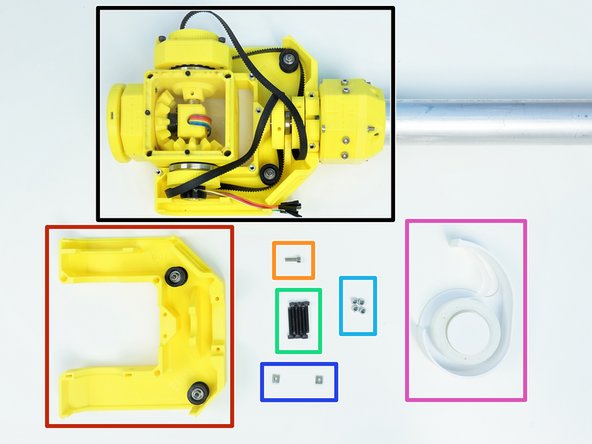

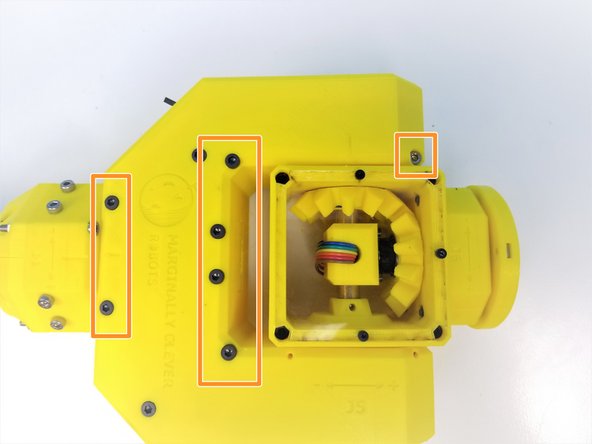

Assembled Picasso Box

-

Assembly Ulna Gearbox & Elbow Tail

-

[3D] - 6E Picasso Wrist Gearbox Components

-

[3D] - 5A Fork Components

-

Alan Keys

-

Socket Head Driver

-

Plier [Opt.]

-

-

-

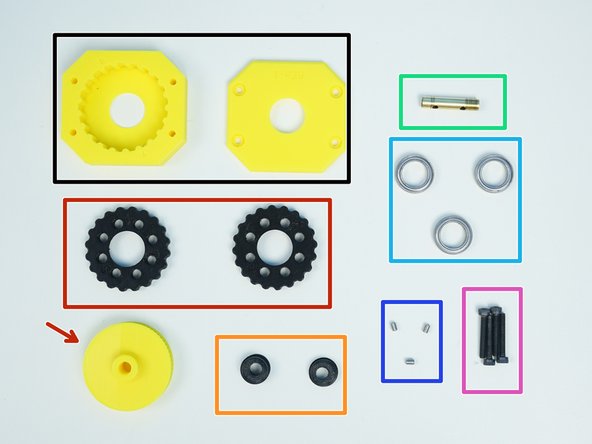

Prepare the following components:

-

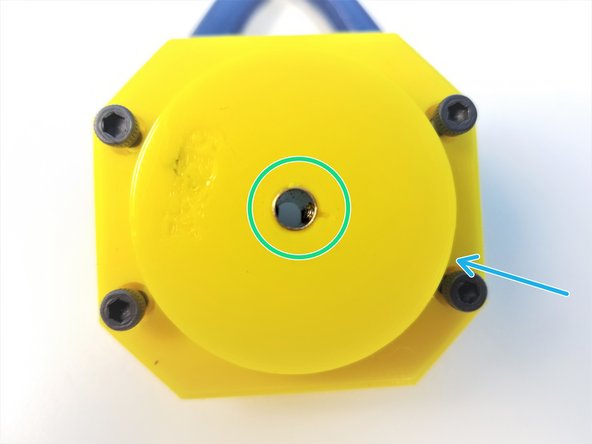

Assembled Picasso Box

-

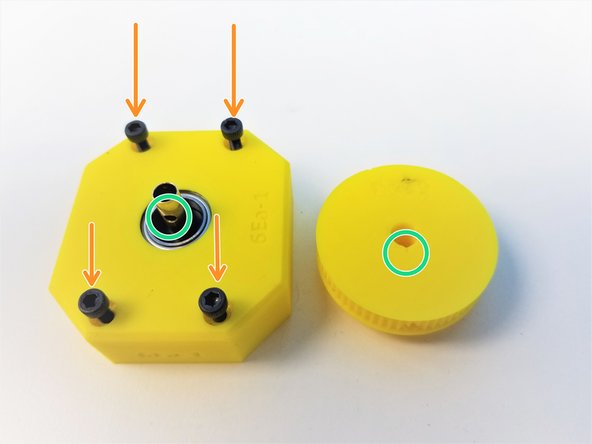

[3D] - 6Ea Picasso GB Output Disks

-

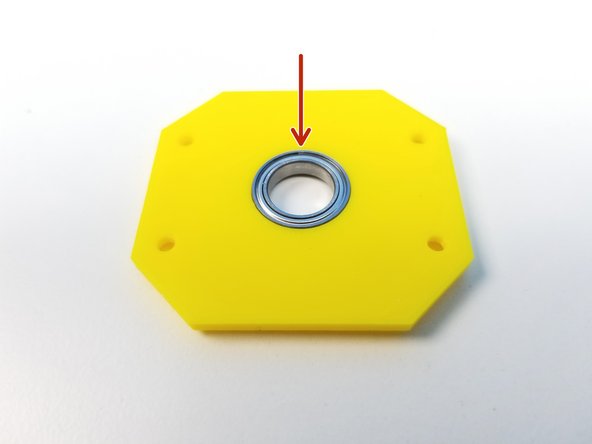

6706 Bearing [30x37x4mm] (x1)

-

M3x10mm Screws (x4)

-

M3x20mm Screws (x8)

-

M3 Hex Nuts (x8)

-

-

-

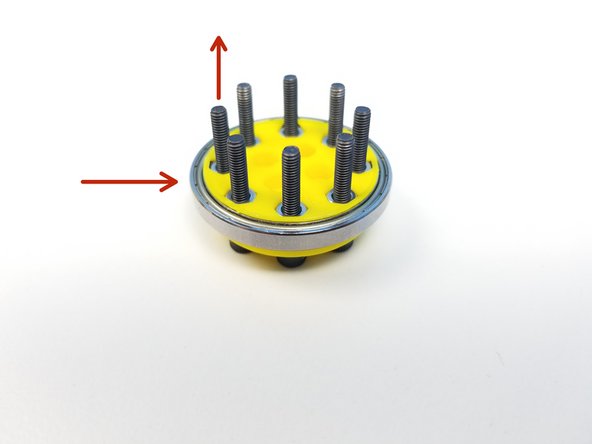

Clamp 6706 Bearings with two Output Disk components using M3x20mm screws and Hex Nuts

-

Tighten these nuts as well

-

Align the 4 Middle Holes of Clamped Output Disk to the side of the Picasso Box

-

Secure the clamped output disk to the side of the Assembled Picasso Box using M3x10mm Screws

-

-

-

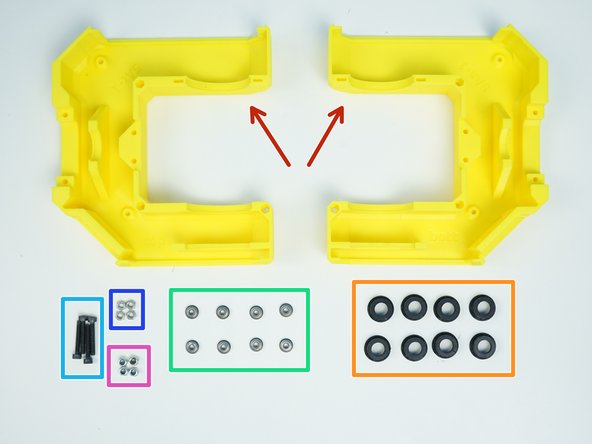

Prepare the following components:

-

[3D] - 6Ea Picasso GB Housing

-

[3D] - 6Ea Picasso GB Rotors & 6PE Pulley Gear

-

[3D] - 6Ea Picasso GB Eccentric Cams

-

Brass Tube [7/32' x 25.95mm]

-

6701 Bearings [12x18x4mm] (x3)

-

M3x4mm Set Screws (x3)

-

M3x20mm Screws (x4)

-

-

-

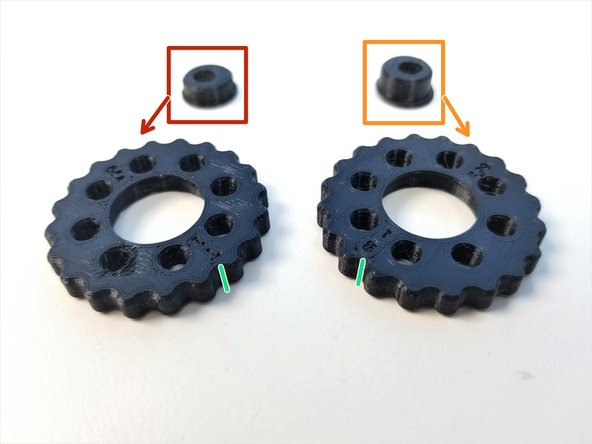

Eccentric Cams

-

"Thin/Top" Eccentric Cam

-

"Thick/Bottom" Eccentric Cam

-

Rotors

-

Make a sharpie mark on the side of the Rotor where it lines up with the B and T label on each Rotors

-

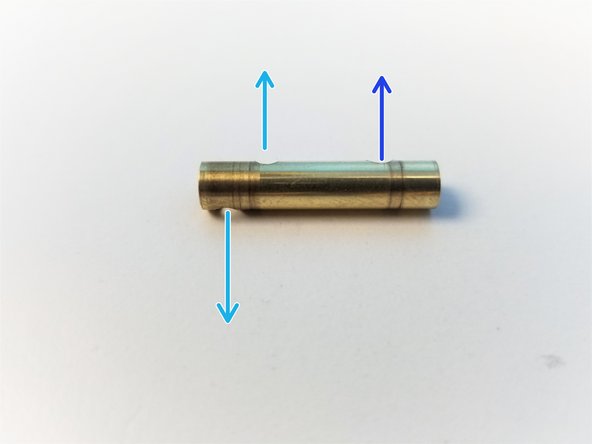

Brass Tube

-

Tube end with the two drilled holes = Cam End

-

Tube end with the one drilled hole = Pulley End

-

-

-

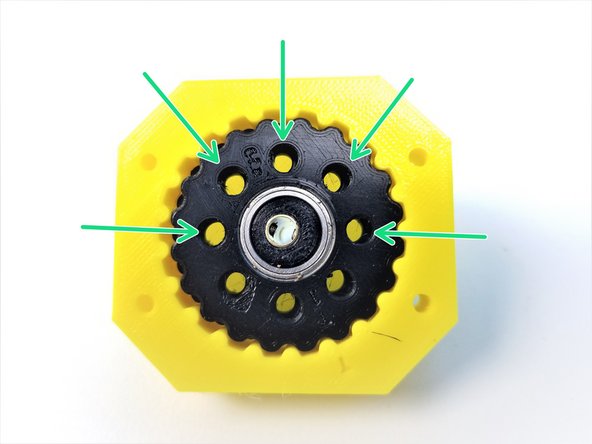

Insert 6701 Bearings to both Top and Bottom Rotors as well as the Top Housing

-

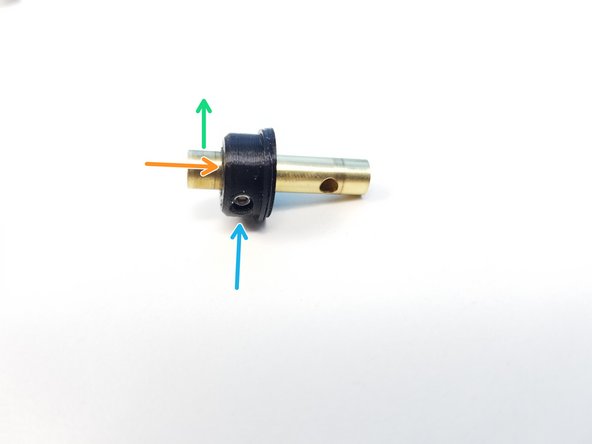

Slide the Bottom Eccentric Cam to the 2nd hole from the edge in the Cam End of the Brass Tube

-

First hole is on the other side of the Tube

-

Align the set screw holes and screw its place using the M3x4mm Set Screw

-

-

-

Slide the Bottom Rotor to the Bottom Eccentric Cam

-

Label Side of the Rotor is facing the Cam End

-

Repeat the process with the Top Eccentric Cam and Rotor

-

Label Side of the Rotor is facing the Cam End

-

-

-

Align the Side Sharpie mark on the Bottom Rotor to the "B" label on the Housing and slide only the Bottom Rotor into the Housing

-

Align the Side Sharpie mark on the Top Rotor to the "T" labelled on the Housing and slide the rest of the Rotor in.

-

If everything went smoothly, the gap between 8 holes on each rotor should be equally spaced

-

-

-

Insert 6701 Bearing on the Top Housing

-

Secure the Top Housing to the Rotor Housing using the M3x20mm Screws

-

DON't screw all the way in. Just to the flushed to the bottom of the Main Housing

-

Align the Pulley Gear to the Set Screw and slide in the Pulley gear to the Brass Tube

-

Secure it using M3x4mm Set Screw

-

-

-

Prepare the following components:

-

[3D] - 5Aa Fork {Bottom & Top}

-

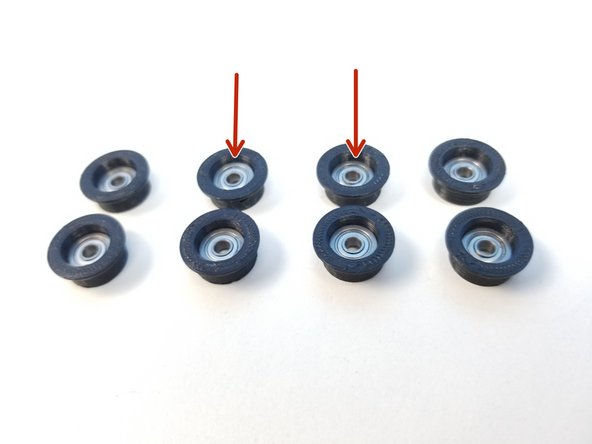

[3D] - 5I Idler Bearing Cover (x8)

-

MF83 Flanged Bearings [3x8x4mm] (x8)

-

M3x20mm Screws (x4)

-

M3 Hex Nuts (x4)

-

M3 Nylock Nuts (x4)

-

-

-

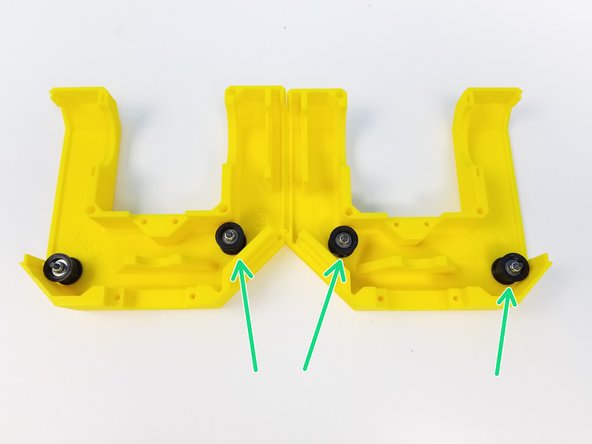

Insert MF83 Bearings into the Bearing Sleeves

-

Insert the M3x20mm Screw in to the Fork Half where there's a chamfered peg on the inner face

-

Slide one of the Bearing Sleeves to the M3x20mm Screwss with the flanged part on the bottom

-

Use M3 Hex Nut to secure the Bearing Sleeve in place

-

-

-

Insert another one of the Bearing Sleeves on the M3x20mm Screws but this time with the flanged part facing up

-

Use M3 Nylock Nuts to secure it in place

-

Repeat the procedure for 3 other locations.

-

-

-

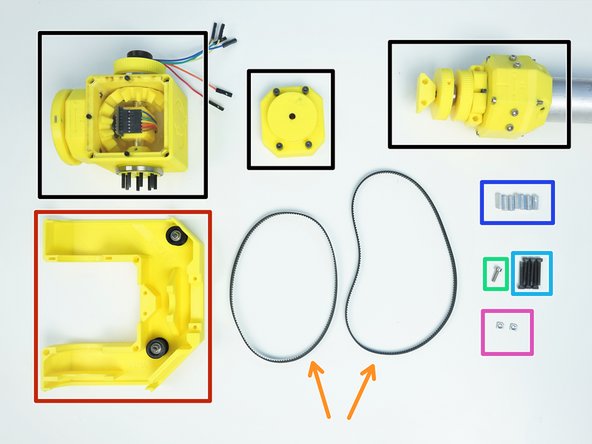

Prepare the following components:

-

Assembled Ulna Gearbox, Picasso Box and Wrist Gearbox

-

Fork Bottom {w/ Idler installed}

-

Timing Belt GT2-336mm & GT2-400mm

-

M3x10mm Screw (x1)

-

M3x22mm Screws (x6)

-

M3x4.5x12mm Hex Standoffs (x7)

-

M3 Square Nuts (x2)

-

-

-

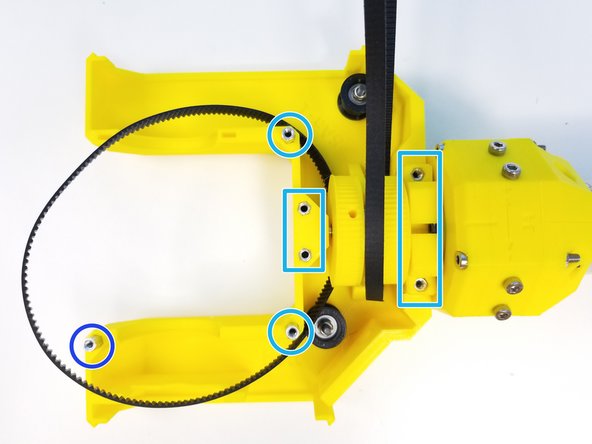

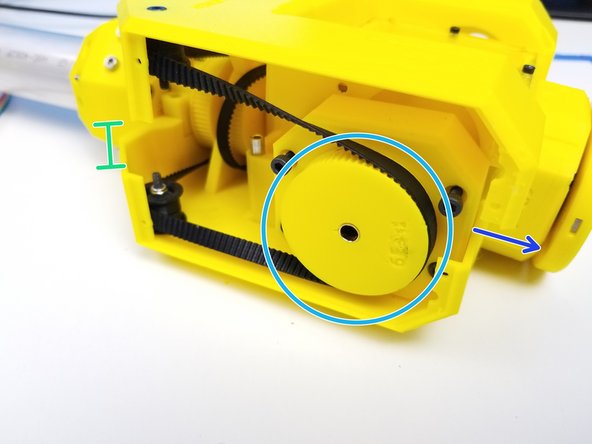

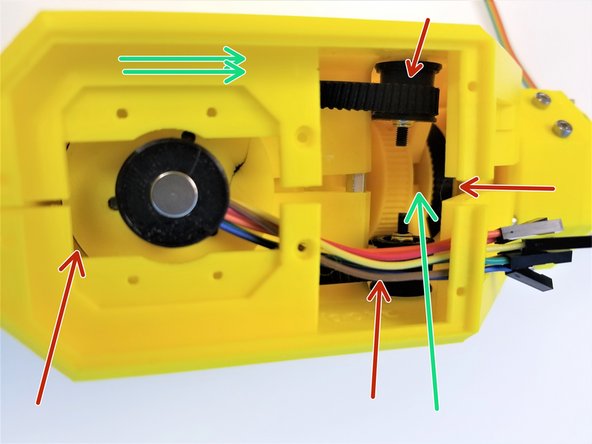

Place the GT2x400mm Timing Belt on the outer pulley on Assembled Ulna Gearbox

-

Place the GT2x336mm Timing Belt on the inner pulley

-

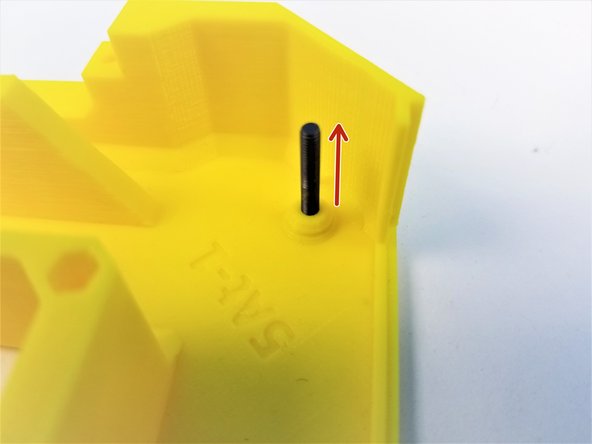

Align the Ulna Sensor Plate and Ulna Output Gearbox to the Fork Bottom with the Hex Standoff insert pointing upward

-

Insert M3x4.5x12mm Hex standoffs and secure its place using M3x22mm Screws

-

Use M3x10mm Screw in this location

-

-

-

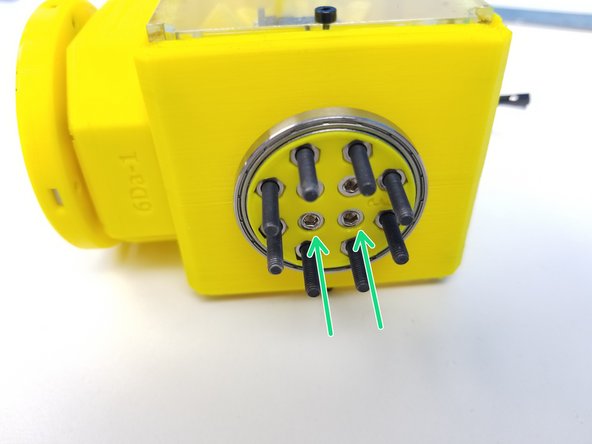

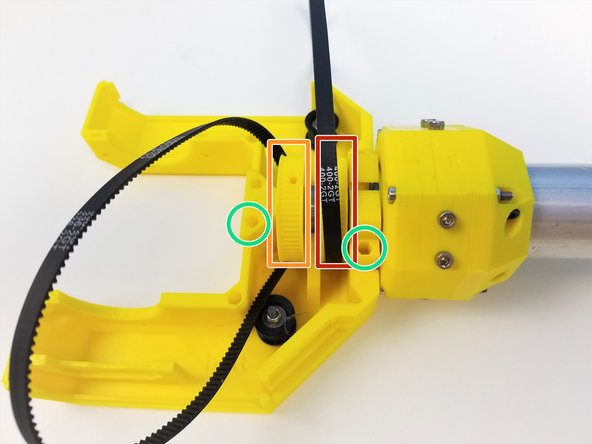

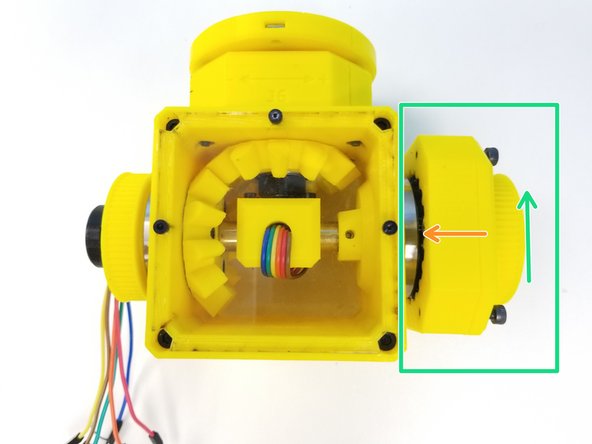

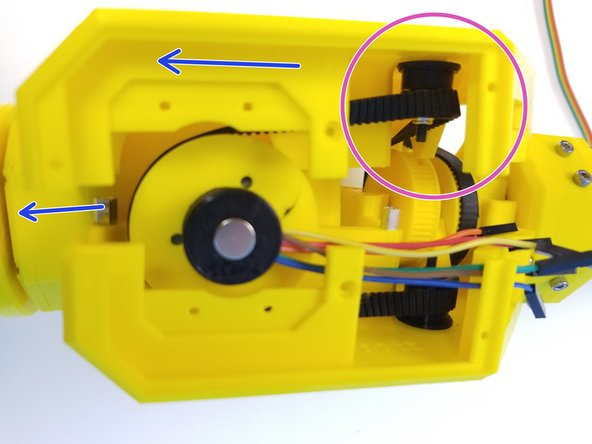

Insert the Picasso Output pins to the Picasso Gearbox

-

Rotate the Input Pulley of the Picasso Gearbox to align the gearbox housing

-

Insert the assembled Picasso Box into the Bearing Slots of the Fork Bottom

-

Make sure to wrap the Timing Belts on both Pulley Gears AND the Bottom Idlers

-

The SMOOTH SIDE of the Belt on the IDLERS

-

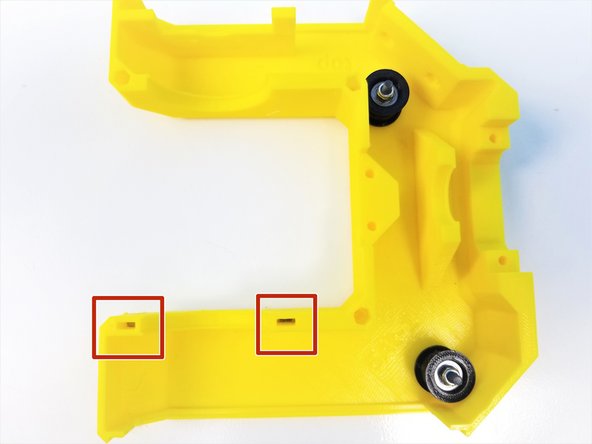

Insert M3 Square Nuts in the Square Nut insert on the Fork Bottom

-

Secure the Picasso Gearbox by tightening the bottom screws on the Gearbox Housing

-

-

-

Prepare the following components:

-

Fork Bottom Prepared

-

Fork Top {w/ Idlers Installed}

-

M3x10mm Screw (x1)

-

M3x25mm Screws (x6)

-

M3 Nylock Nuts (x4)

-

M3 Square Nuts (x2)

-

[Opt.] - Tape

-

-

-

Insert the M3 Square Nuts in the Fork Top

-

Insert the M3 Nylock Nuts in both Fork Top and Bottom on the side wall

-

Optionally, put tape over the nuts as the friction fit alone may not be enough to keep them on.

-

-

-

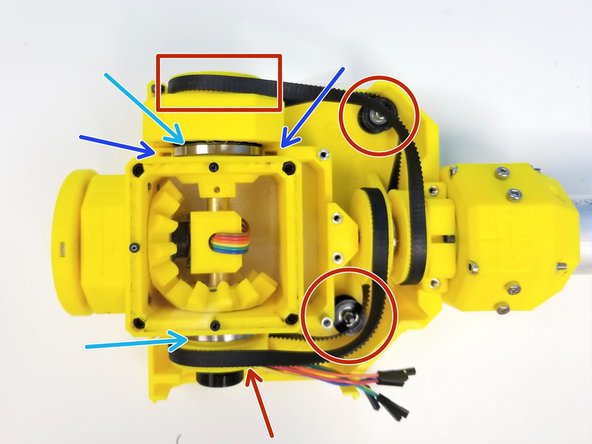

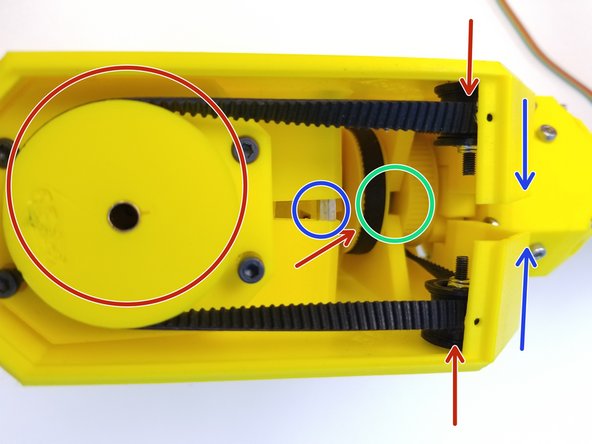

This step may be the hardest to execute so follow through carefully. Use Alan Key as a "hook" if you need to

-

Align the 400mm GT2-Timing Belt {outer belt} to the Top Idler

-

Take the Belt off of the Gearbox Pulley if you need to.

-

Make sure the SMOOTH side of the belt is on the Idler

-

Rotate the Top Fork and let it FLOAT over the Bottom Fork

-

Put the 400mm Belt back on the Pulley

-

Notice that the Top Fork is shifted forward relative to the Bottom Fork

-

While the Fork is shifted forward, put the 336mm GT2-Timing Belt on the Inner Pulley on the other side

-

-

-

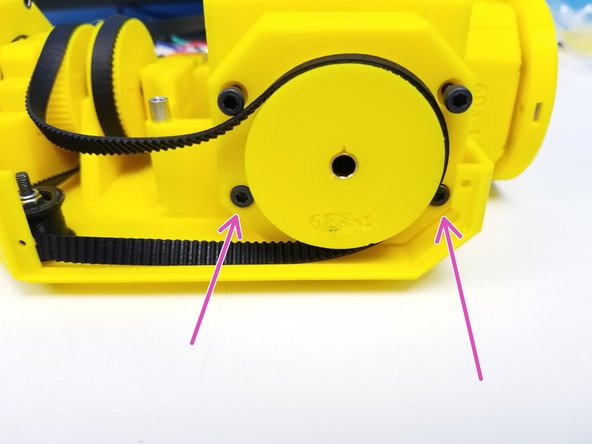

Make sure the both Inner and Outer Belts are on ALL the Pulley Gears

-

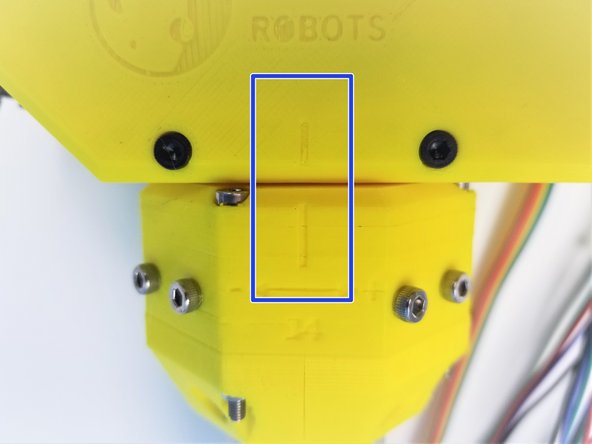

Shift the Top Fork back and align the "Pulley Separating Wall"

-

Double check that the Picasso Gearbox Side is all good too

-

Once all Hex Standoffs are aligned too, Clamp the Top Fork down

-

-

-

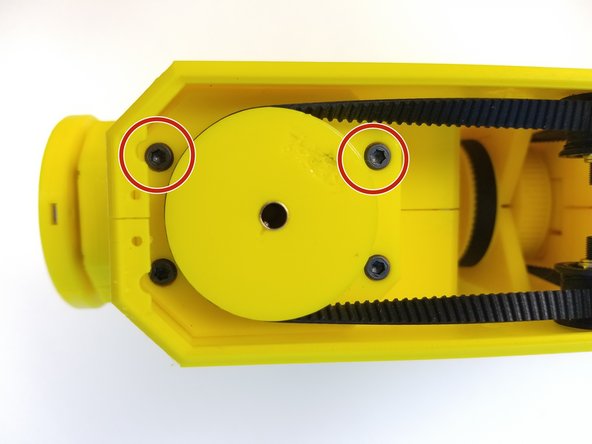

Secure the Picasso Gearbox to the Top Fork by tightening the top screws on the Housing

-

Use M3x25mm Screws and M3x10mm screw to secure the Top Fork to the Bottom Fork

-

-

-

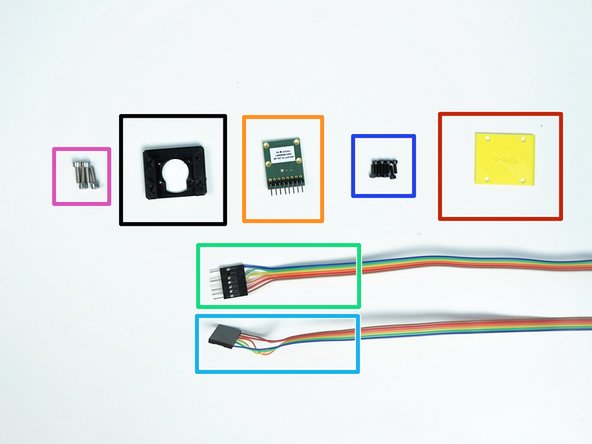

Prepare the following components:

-

[3D] - Sensor Adapter 2

-

[3D] - Fork Cable Clamp Plate

-

AS5147 Sensor {right angle header on the label side}

-

Hand Sensor Cable Extension {numbered 5w/ male connector}

-

Wrist Sensor Cable {numbered 4}

-

M2x6mm Screws (x8)

-

M3x10mm Screws (x4)

-

-

-

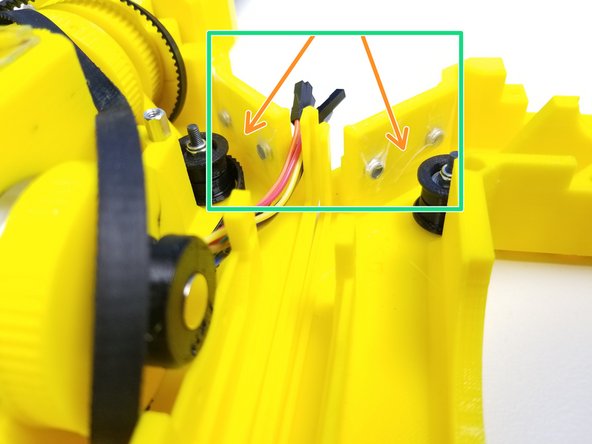

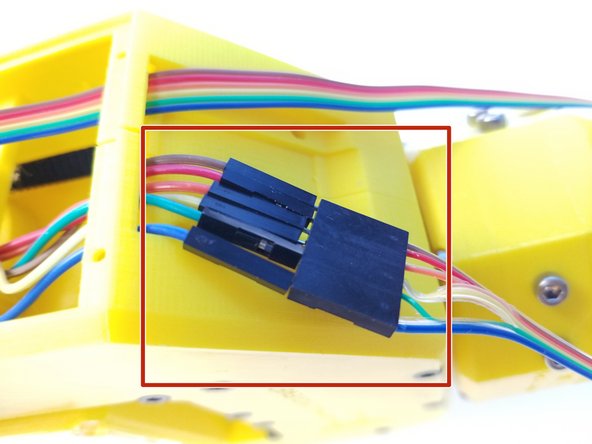

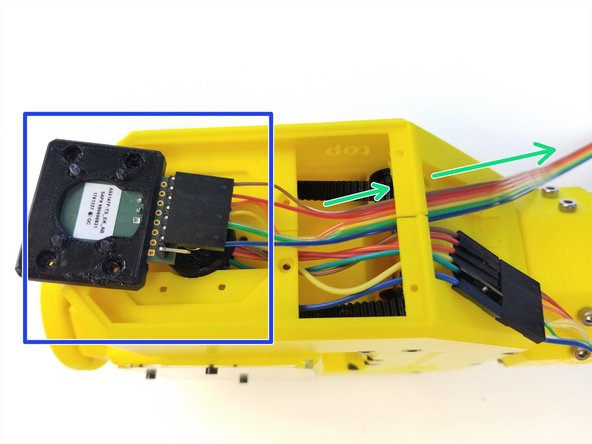

Connect the Hand Sensor Cable Extension to the Wires that comes out of the Picasso Box {Hand Sensor}

-

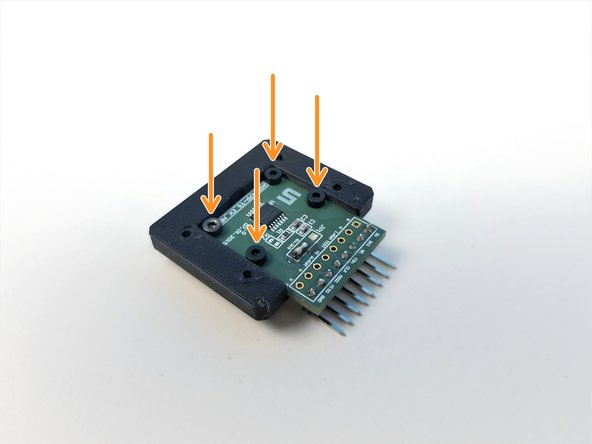

Mount AS5147 Sensor to the Sensor Adapter 2 using M2x6mm Screws

-

Insert the Wrist Sensor Cable {Female} through the Cable Clamp

-

Connect the Wrist Sensor Cable to AS5147 Sensor

-

If you don't remember the Connection Orientation from previous steps, just copy the picture.

-

-

-

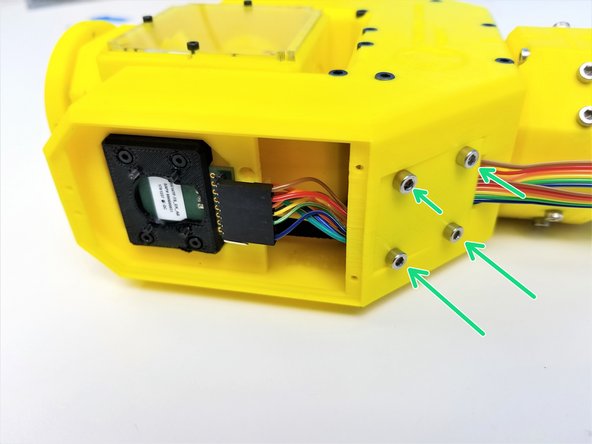

Use M2x6mm Screws to secure the Sensor Adapter to the Fork

-

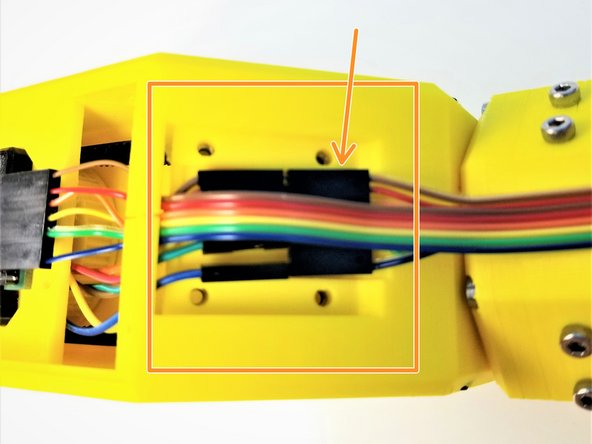

Organize the Cables on the Cable Clamp area

-

The Hand Sensor Connector is below the Wrist Sensor Cable

-

Use M3x10mm Screws to clamp the sensor cables with Fork Cable Clamp Plate

-

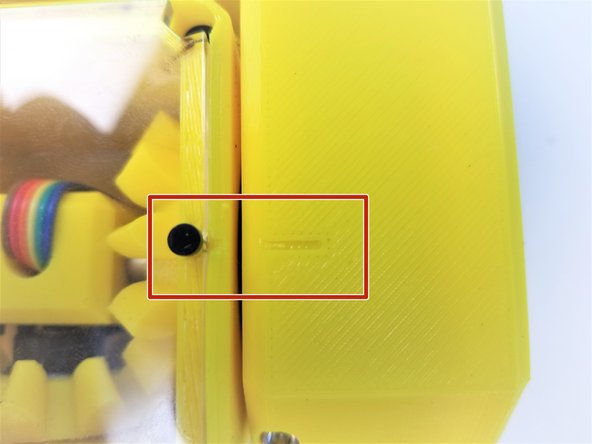

There's only one orientation that the Clamp Plate can go on,

-

Make sure the Version Label is facing the Cable

-

Chamfered Part is where the Cable comes Out

-

-

-

Prepare the following components:

-

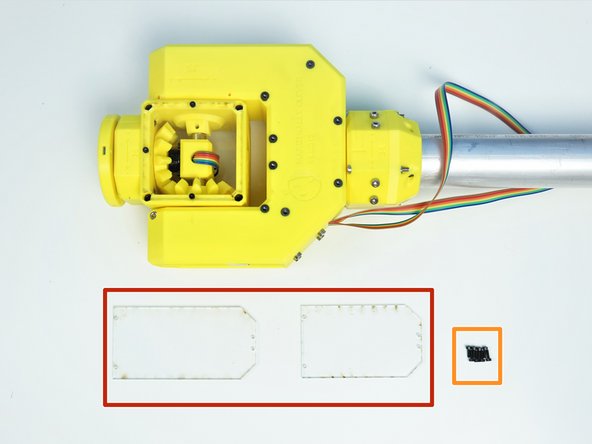

[LSR] - Fork Acrylic Plates {Large & Small}

-

M2x6mm Screws (x8)

-

Small Acrylic Plate goes on the Sensor Side

-

Large one goes on the Wrist Gearbox Side

-

Secure them with M2x6mm Screws

-

-

-

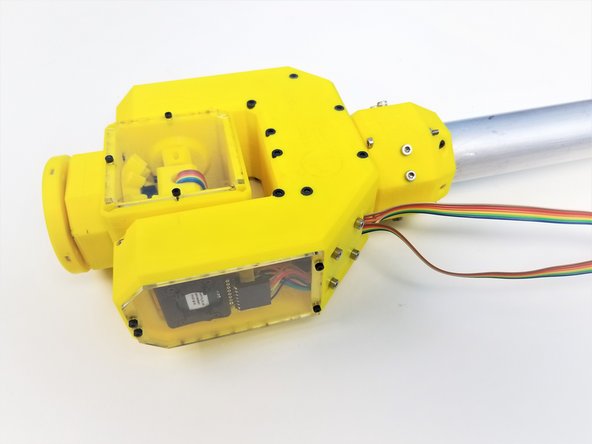

Rotate the Motor Shafts on the Elbow Tail Side to rotate the joints

-

Align the Picasso Box to the Fork

-

Align the Fork to the Ulna Gearbox

-

-

-

Congratulation! You are nearly there!!!

-

![[LSR] - Fork Acrylic Plates {Large & Small}](https://d3t0tbmlie281e.cloudfront.net/igi/mcr/3BYQU4p6n3x2opJu.medium)